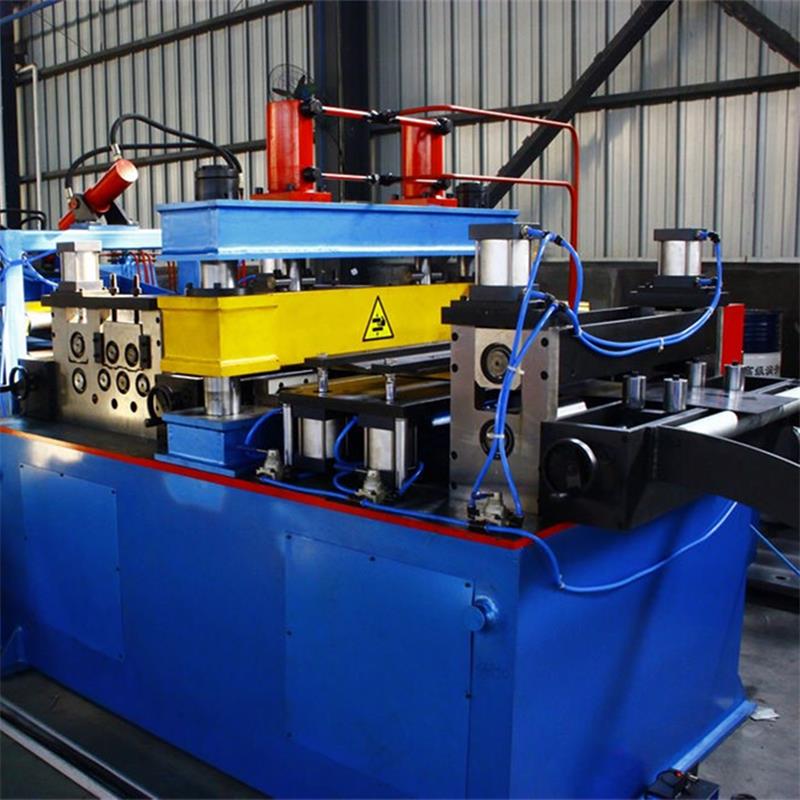

Well-designed Perforated Cable Tray Manufacturing Machine - Storage Shelf Rack Roll Forming Machine – Raintech

Well-designed Perforated Cable Tray Manufacturing Machine - Storage Shelf Rack Roll Forming Machine – Raintech Detail:

MAIN TECHNICAL PARAMETERS

| Configurations | 3T Manual Uncoiler(2 SETS), Roll Forming, Electric-Motor, Mould Cutting, hydraulic station, Control Cabinet |

| Control System | Automatic Colored Touch ScreenDelta brand PLC Inverter |

| Main Power | 7.5 KW |

| Pump Power | 4 KW |

| Power Supply | 380V, 3-Phase, 50Hz |

| Forming Speed | 8-10 m/min |

| Roll Station | 17 roller station |

| Shaft Diameter | 57mm |

| Feeding Thickness | 1.8mm |

| Overall Size | About 7200×1200×1500mm |

| Total Weight | Approximately 3600KGS |

PRODUCTION PROCESS

Uncoiling → Leveling → Servo Feeding → Punching → Roll Forming → Cutting → Discharging

MAIN COMPONENTS

Uncoiler: automatically release the material coil according to the speed of the whole line

Servo Feeding Machine: Feed the sheet according to the actual step length required for punching

Punching press: Used to punching holes in the plate

Roll Forming Machine: Used to achieve the final required interface shape through the roll forming process of the required finished plate shape

Cutting Machine: It is to cut the formed work piece to length

Electrical Control Unit: The unit is equipped with PLC and tough screen, it control the whole production line.

Hydraulic Station: Provide power for punching machine and cutting machine

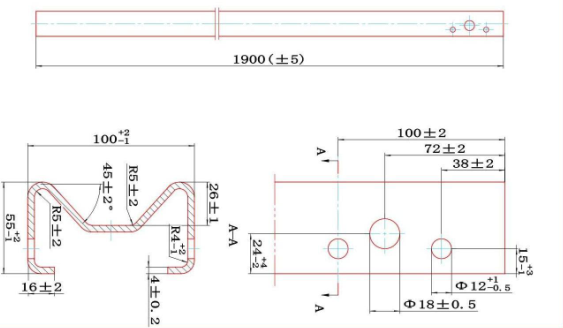

WORKPIECE SAMPLES

APPLICATION

The roll forming production line is used to produce storage racks for warehouse and storage frame.

Product detail pictures:

Related Product Guide:

Our organization has been focusing on brand strategy. Customers' gratification is our greatest advertising. We also source OEM provider for Well-designed Perforated Cable Tray Manufacturing Machine - Storage Shelf Rack Roll Forming Machine – Raintech , The product will supply to all over the world, such as: Switzerland, Johor, Munich, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, please feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our products, please feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!