Wholesale Full Automatic Pallet Rack Uprights Multi Sizes in 1 Machine Storage Upright Rack Roll Forming Machine Shelf Machine

We not only will try our greatest to supply outstanding services to every shopper, but also are ready to receive any suggestion offered by our buyers for Wholesale Full Automatic Pallet Rack Uprights Multi Sizes in 1 Machine Storage Upright Rack Roll Forming Machine Shelf Machine, For high quality gas welding & cutting equipment supplied on time and at the right price, you can count on company name.

We not only will try our greatest to supply outstanding services to every shopper, but also are ready to receive any suggestion offered by our buyers for China Pallet Rack Forming Machine and Storage Shelf Forming Machine, Our solutions are mainly exported to Europe, Africa, America, the Middle East and Southeast Asia and other countries and regions. We now have enjoyed a great reputation among our customers for quality products and good services.We would make friends with businessmen from at home and abroad, following the purpose of “Quality First, Reputation First, the Best Services.”

MAIN TECHNICAL PARAMETERS

| Configurations | 3T Manual Uncoiler(2 SETS), Roll Forming, Electric-Motor, Mould Cutting, hydraulic station, Control Cabinet |

| Control System | Automatic Colored Touch ScreenDelta brand PLC Inverter |

| Main Power | 7.5 KW |

| Pump Power | 4 KW |

| Power Supply | 380V, 3-Phase, 50Hz |

| Forming Speed | 8-10 m/min |

| Roll Station | 17 roller station |

| Shaft Diameter | 57mm |

| Feeding Thickness | 1.8mm |

| Overall Size | About 7200×1200×1500mm |

| Total Weight | Approximately 3600KGS |

PRODUCTION PROCESS

Uncoiling → Leveling → Servo Feeding → Punching → Roll Forming → Cutting → Discharging

MAIN COMPONENTS

Uncoiler: automatically release the material coil according to the speed of the whole line

Servo Feeding Machine: Feed the sheet according to the actual step length required for punching

Punching press: Used to punching holes in the plate

Roll Forming Machine: Used to achieve the final required interface shape through the roll forming process of the required finished plate shape

Cutting Machine: It is to cut the formed work piece to length

Electrical Control Unit: The unit is equipped with PLC and tough screen, it control the whole production line.

Hydraulic Station: Provide power for punching machine and cutting machine

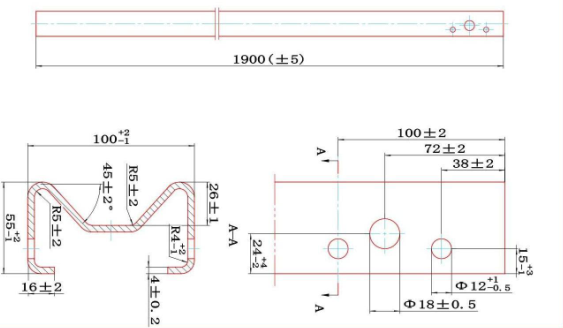

WORKPIECE SAMPLES

APPLICATION

The roll forming production line is used to produce storage racks for warehouse and storage frame.

Shelf equipment, shelf roll forming machine is widely used for cold roll forming of storage shelves, supermarket shelves,heavy-duty shelves and other profiles.