Wholesale Steel Roll Former Storage Rack Roll Forming Machine with High Speed

Our well-equipped facilities and exceptional top quality handle throughout all stages of production enables us to guarantee total client fulfillment for Wholesale Steel Roll Former Storage Rack Roll Forming Machine with High Speed, We consider you will be contented with our fair rate, good quality items and fast delivery. We sincerely hope you can give us an option to serve you and be your ideal partner!

Our well-equipped facilities and exceptional top quality handle throughout all stages of production enables us to guarantee total client fulfillment for China Storage Rack Roll Forming Machine and Rack Roll Forming Machine, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to offer our clients sincerely with qualified products, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

MAIN TECHNICAL PARAMETERS

| Configurations | 3T Manual Uncoiler(2 SETS), Roll Forming, Electric-Motor, Mould Cutting, hydraulic station, Control Cabinet |

| Control System | Automatic Colored Touch ScreenDelta brand PLC Inverter |

| Main Power | 7.5 KW |

| Pump Power | 4 KW |

| Power Supply | 380V, 3-Phase, 50Hz |

| Forming Speed | 8-10 m/min |

| Roll Station | 17 roller station |

| Shaft Diameter | 57mm |

| Feeding Thickness | 1.8mm |

| Overall Size | About 7200×1200×1500mm |

| Total Weight | Approximately 3600KGS |

PRODUCTION PROCESS

Uncoiling → Leveling → Servo Feeding → Punching → Roll Forming → Cutting → Discharging

MAIN COMPONENTS

Uncoiler: automatically release the material coil according to the speed of the whole line

Servo Feeding Machine: Feed the sheet according to the actual step length required for punching

Punching press: Used to punching holes in the plate

Roll Forming Machine: Used to achieve the final required interface shape through the roll forming process of the required finished plate shape

Cutting Machine: It is to cut the formed work piece to length

Electrical Control Unit: The unit is equipped with PLC and tough screen, it control the whole production line.

Hydraulic Station: Provide power for punching machine and cutting machine

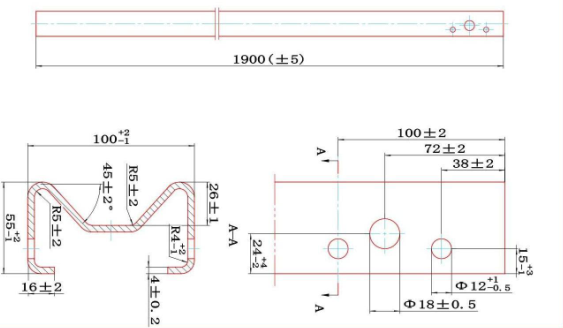

WORKPIECE SAMPLES

APPLICATION

The roll forming production line is used to produce storage racks for warehouse and storage frame.

Our well-equipped facilities and exceptional top quality handle throughout all stages of production enables us to guarantee total client fulfillment for Wholesale Steel Roll Former Storage Rack Roll Forming Machine with High Speed, We consider you will be contented with our fair rate, good quality items and fast delivery. We sincerely hope you can give us an option to serve you and be your ideal partner!

Wholesale China Storage Rack Roll Forming Machine and Rack Roll Forming Machine, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to offer our clients sincerely with qualified products, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.