2019 High quality High Quality Two Wave Crash Barrier Guardrail Roll Forming Machine

We now have our individual sales group, layout team, technical team, QC crew and package group. Now we have strict high-quality control procedures for each procedure. Also, all of our workers are experienced in printing discipline for 2019 High quality High Quality Two Wave Crash Barrier Guardrail Roll Forming Machine, We, with great passion and faithfulness, are willing to provide you with perfect services and striding forward with you to create a bright future.

We now have our individual sales group, layout team, technical team, QC crew and package group. Now we have strict high-quality control procedures for each procedure. Also, all of our workers are experienced in printing discipline for China Roll Forming Machine for Roadworks and Guardrail Forming Machine, Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of “human-oriented and faithful service”, with an aim to gain global recognition and sustainable development.

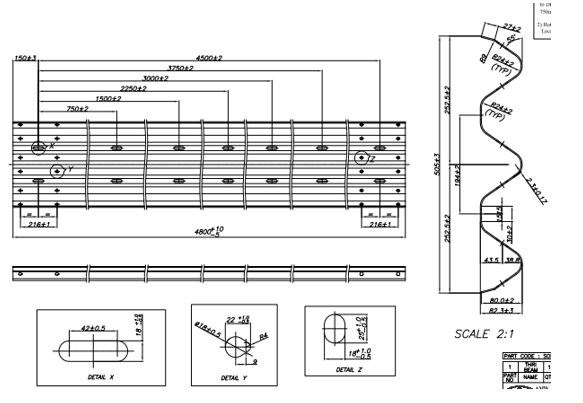

MAIN TECHNICAL PARAMETERS

| Material | Cold rolled low carbon steel |

| Server system | YASKAWA |

| Steel belt width | ≤750mm |

| Production line speed | 15m/min |

| Electric control unit | PLC(Mitsubishi) |

MAIN COMPONENTS

1. Uncoiler

The machine is a single-head mode. With single support, the motor drives the material shaft of the uncoiler to release the material roll, and the hydraulic power drives the tension device of the material shaft of the uncoiler to fix the material roll on the material shaft of the uncoiler.

2. Uncoiler Parameter

| Allowable coil inner diameter | Ф508mm |

| Maximum allowable roll diameter | Ф1600mm |

| Maximum allowable roll width | 500 mm |

| Maximum roll carrying weight | ≤5000 kg |

| Uncoiler motor power | ≈5.5Kw (subject to the final design) |

3. Leveling Servo Feeder

The front of the leveling machine is also equipped with a telescopic shovel head and a material pressing device to ensure that the raw material rolls enter the leveling machine smoothly and safely.

| Maximum working speed | 40 m/min |

| Maximum leveling roll width | 500mm |

| Adapt to the maximum roll thickness | 2mm |

| Motor power of leveling machine: | ≈7.5Kw(subject to the final drawing design) |

4. Roller Forming Machine

The forming unit adopts an independent frame (housing mode). Motor, reducer drive, gear and chain drive.

| Forming Passes | about 13 |

| Shaft diameter of forming machine | φ80mm(subject to the final design) |

| Motor Power | about 55W(subject to the final design |

| Max. speed | 10~15m/min |

WORKPIECE SAMPLES

This is a 3 wave barrier made by our production equipment.

APPLICATION

Guardrails are widely used in industry, agriculture, municipal administration, transportation and other industries for decoration, maintenance and protection.

A crash barrier forming machine is a type of machinery used to manufacture crash barriers or guardrails. These barriers are used to provide safety and protection on roads and highways, preventing vehicles from veering off the road or into oncoming traffic.

This machine is designed to form crash barriers by forming and joining metal beams or panels. It usually consists of several components such as feeders, roll forming stations, cutting devices and conveyor systems. The feeder feeds the metal sheet or coil to the roll forming station where it is formed into the desired crash barrier profile. A cutting device then cuts the formed barrier to the required length, and a conveyor transports the finished barrier for further processing or packaging.

The size and capacity of crash barrier forming machines may vary depending on the specific requirements of the project or manufacturer. They are usually automated and can be controlled by computer systems, allowing precise and efficient production.

These machines play a vital role in the manufacture of crash barriers, ensuring high quality and durable barriers are produced to enhance road safety.