2023 High Quality 1100 Glazed Roof Tile Roll Forming Machine

Well-run equipment, specialist income crew, and better after-sales services; We’re also a unified major family, anyone stay with the organization value “unification, determination, tolerance” for 2023 High Quality 1100 Glazed Roof Tile Roll Forming Machine, Our tenet is evident all of the time: to deliver high quality solution at competitive price tag to clients throughout the planet. We welcome potential customers to get in touch with us for OEM and ODM orders.

Well-run equipment, specialist income crew, and better after-sales services; We’re also a unified major family, anyone stay with the organization value “unification, determination, tolerance” for China Metal glazed tile roll forming machines, Welcome to visit our company, factory and our showroom where displays various goods that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to offer you the best service. Make sure you contact us if you require more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.

PRODUCT DESCRIPTION

This glazed tile roll forming machine is used for making the glazed tile,which is widely used in factories, houses, hotels, villas and other industrial and civil buildings.

MAIN PARAMETERS

Material: Galvanized sheet

Yield strength of raw materials: ≤235Mpa

Tensile strength of raw materials: ≤550Mpa

Outer Diameters of Coils: ≤Ф1300 mm

Inner Diameter of Coils: Ф508

Steel strap width: ≤1000mm

Steel Strap Thickness: 0.2~0.4mm

Weight/Coil: ≤5000 kg

PRODUCTION PROCESS

The glazed tiles manufacturing machine products are carried out according to the following process:

Uncoiling → Looper (Storage) → Cold Forming → Pressing Table & Cutting → Discharging

MAIN COMPONENTS&SPECIFICATION

| No | Items Name | Specifications |

| 1 | Decoiler | Manual Type; Coils ID: Ф508mm; Coil OD: Ф1300mm; Coil Width: 1000mm; Coil weight: ≤5000 kg |

| 2 | Roll Forming Machine | The forming unit is driven by motor, reducer and sub-reducer. Molding machine memorial arch for independent memorial arch structure (non – plate structure), stable performance, reliable, high precision. The base is welded steel structure. Annealing after welding.The molding roller is designed by professional software, and the material is made of high quality 45 steel and hard chrome plating. Forming passes: 16 passes (subject to the final design); Shaft diameter: φ70mm (subject to final design); Motor power: 5.5kw Maximum linear speed: 2~5 m/min |

| 3 | Hydraulic Cutting | Cutter mode adopts no scrap cutting. Cutter material: Cr12MoV (hardness is HRC58~62 after quenching); Measuring accuracy: ±1.5mm |

| 7 | Electrical Control Cabinet | PLC: Mitsubishi; Inverter: Delta; Touch screen: Vinylon (Taiwan, China); Low-voltage electrical appliances: Schneider (France); Encoder: Omron (Japan) |

| 8 | Hydraulic System | Hydraulic system USES filter, the cleanliness of oil to ensure 6-8 grade |

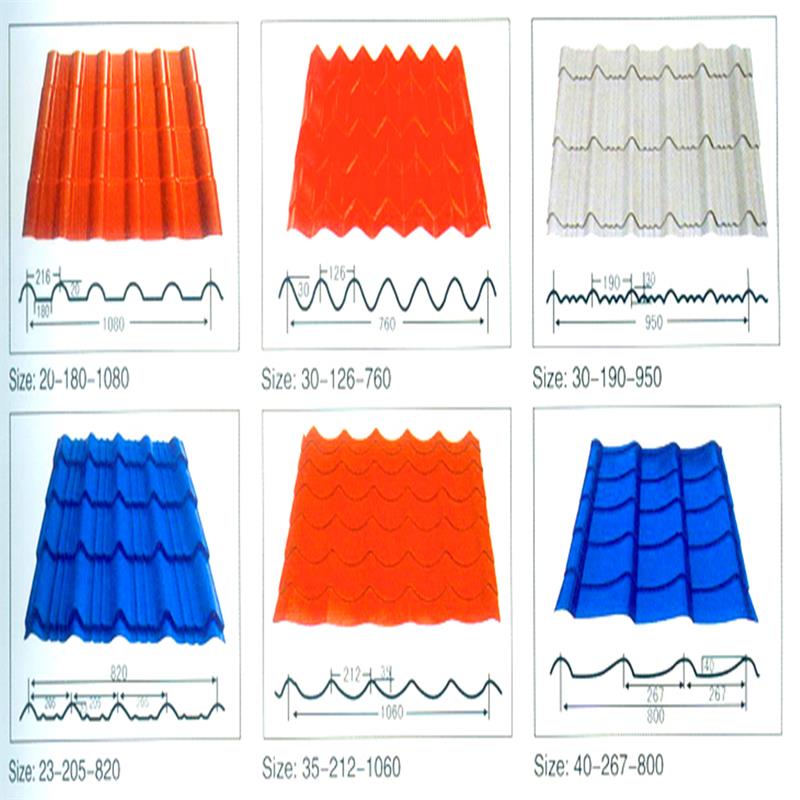

WORKPIECE SAMPLES

Glazed tile roll forming machine;glazed tiles manufacturing machine;glazed tile forming machine

Glazed tile roll forming machines are advanced equipment designed for the production of high-quality glazed tiles with sleek design, durability, and excellent finish. These machines are designed to provide high accuracy and precision in tile forming, making them the ideal choice for applications that demand superior product quality.

The glazed tile roll forming machines are designed to suit various applications, including roofing, cladding, and wall paneling. They come in different sizes and configurations to meet the needs of different customers, and are highly versatile and flexible machines capable of processing a wide range of materials.

The machines are widely used in various industries, including construction, architecture, and manufacturing. They are a crucial component in building construction, providing excellent roofing solutions for homes, offices, and other commercial structures. They are also useful in manufacturing and industrial applications, where high-quality glazed tiles are used for wall cladding and paneling.

With their advanced technology and high-end engineering, glazed tile roll forming machines offer exceptional benefits. They provide highly efficient and energy-saving production processes, and their low maintenance requirements ensure low operating costs. They are also easy to operate, with user-friendly controls and interfaces that make production processes more streamlined and accessible.

Glazed tile roll forming machines are an essential investment for anyone looking to produce high-quality glazed tiles. Their versatility, flexibility, and superior product quality are unrivaled, making them the ideal choice for various industrial applications. Whether for residential, commercial, or industrial use, glazed tile roll forming machines are a must-have for any modern construction or manufacturing enterprise.