OEM/ODM Manufacturer Hat Shape Omega Profile Light Steel Keel Furring Channel Roll Forming Machine

Our eternal pursuits are the attitude of “regard the market, regard the custom, regard the science” plus the theory of “quality the basic, have faith in the main and management the advanced” for OEM/ODM Manufacturer Hat Shape Omega Profile Light Steel Keel Furring Channel Roll Forming Machine, Our firm is dedicated to giving shoppers with significant and steady high quality goods at aggressive price tag, generating every single customer satisfied with our products and services.

Our eternal pursuits are the attitude of “regard the market, regard the custom, regard the science” plus the theory of “quality the basic, have faith in the main and management the advanced” for China hat channel profile roll forming machines, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade items in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad and create a great future together.

PRODUCT DESCRIPTION

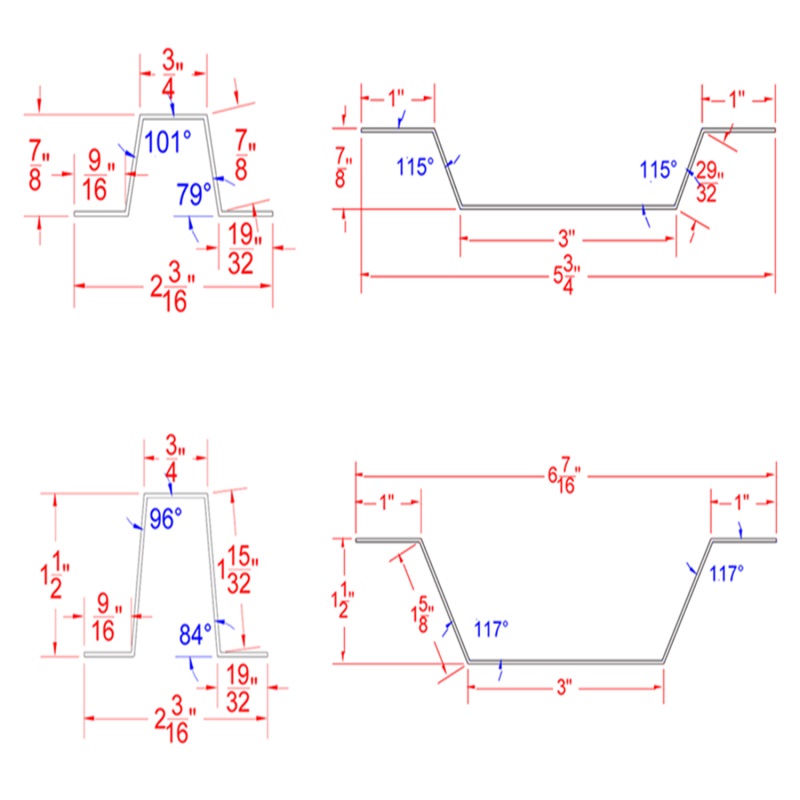

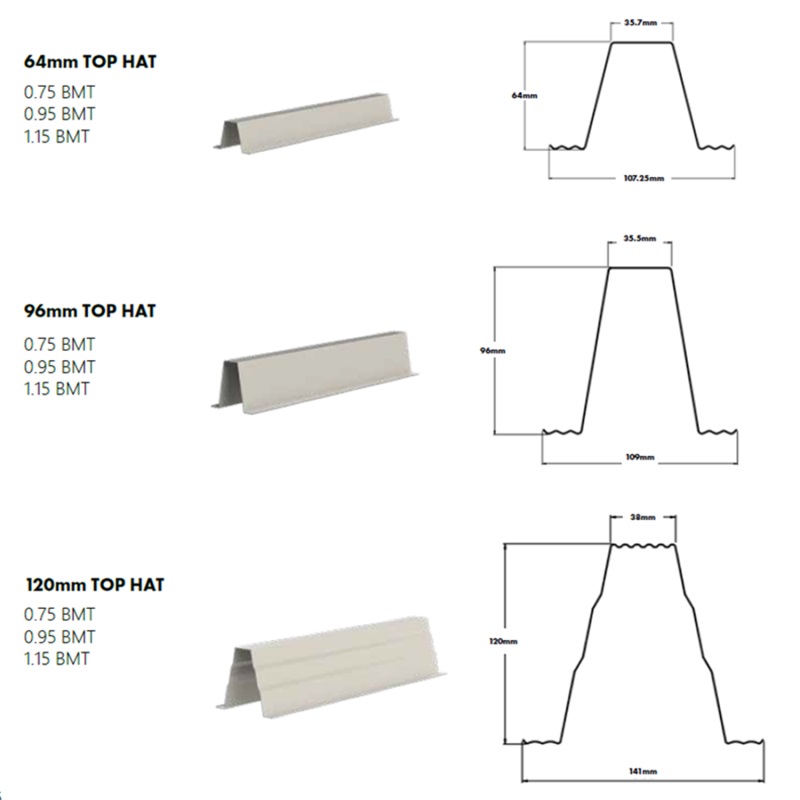

Hat channels are an alternative type of steel roof framing system, which can also be used as a purlin where a lower profile is required, or where the cover system requires closer purlin spacing thus making standard “Z” or “C” purlins overly expensive.

Our hat profile roll forming machine is for making the hat channels, which widely applicable in metal/steel roof construction industries.

MAIN TECHNICAL PARAMETERS

| 1 | Machine structure | Individual archway stands structure |

| 2 | Total power | Motor power-18.5kw Hydraulic power-5.5kw |

| 3 | Roller stations | 18 dots stations |

| 4 | Productivity | 15-25m/min |

| 5 | Decoiler | 3T hydraulic decoiler |

| 6 | Leverling part | Upper is 3 rollers, down is 4 stations(total is 7 rollers) |

| 7 | Drive system | By independent gearbox |

| 8 | Diameter of shaft | ¢60mm solid shaft |

| 9 | Roller material | American D2 D3 |

| 10 | Pre punching& cutting system | Pre-cutting to change the material Material of the punching mold: Cr12 |

| 11 | Hydraulic cutting system | Cr12 with heat treatment 58-60° |

| 12 | Hydraulic power | 7.5KW |

MAIN COMPOSITIONS

|

1 |

Automatic De-coiler | 1. Single head design 2. Loading weight: 3Tons 3. Hydraulic automatic expansion and tightening 4. Suitable width: <300mm 5. Coil ID: ¢500±20mm 6. Coil OD: ≤1200mm |

|

2 |

Servo Feeding Leveling | 1. It adopts 5 rollers for leveling, 2 pairs of guide rollers 2. Maximum leveling roll width: 300mm 3. Adapt to the maximum roll thickness: 1~2mm 4. Maximum working speed: 20 m/min 5. Driven: servo motor |

|

3 |

Multi-functional Punching Machine | 1. 6 punching stations, 2. Servo motor power: 1.3KW 3. Servo motor brand: Japan Yaskawa 4. Suitable width: <300mm 5. Punching mold fast positioning, repeat positioning. |

|

4 |

Roll Forming Machine | 1. Driven system: Motor, reducer, spiral bevel gear drive 2. Main machine power: 15KW*2 Sets, 3. Motor brand: SIEMENS BADE servo motor 4. Module Components fast positioning, repeat positioning 5. Forming stations: 18 groups stations |

|

5 |

Hydraulic Cutting Machine | 1. Hydraulic single station, 2. Cutting force: 30Tons, 3. Cutting type: stop cutting 4. Module Components fast positioning, repeat positioning |

|

6 |

Computer Control Box | 1. Japan Mitsubishi motion controller PLC 2. Japan Yaskawa Servo System 3. With human machine interface touch screen 4. Schneider weak current control |

|

7 |

Hydraulic Station | 1. Hydraulic system power: 15KW 2. Hydraulic value: Huade, 3. With fan cooling system |

PRODUCTION PROCESS

Uncoiling → leveling → Looper (storage) → servo feeding → Multi-stations punching → forming station → Hydraulic cutting → Finished product discharging

WORKPIECE SAMPLES

Hat channel roll forming machine;hat profile forming machine;hat profile channel making machine

The hat channel profile roll forming machine is a highly versatile and efficient machine that is widely used in various industries today. This machine is designed to produce high-quality and accurate metal parts that can be used in construction, automotive, and other manufacturing fields.

One of the primary advantages of this machine is that it can create parts with different thicknesses and sizes quickly and accurately. This saves a lot of time and cost compared to traditional manufacturing methods. Additionally, the hat channel profile roll forming machine can work with different materials such as aluminum, steel, and others, making it a valuable tool for a wide range of applications.

The hat channel profile roll forming machine is ideal for use in applications where precision is paramount. It can produce high-quality parts that meet exacting specifications with minimal waste. Its versatility also means that it can be used in various applications, including roofing and framing systems, curtain wall systems, ceiling systems, partition walls, and more.

Overall, the hat channel profile roll forming machine is an excellent investment for any company looking to improve their manufacturing processes and produce superior quality products. Its versatility, precision, and efficiency make it an invaluable tool for any industry, and it stands to remain a popular choice for many years to come.