8 Years Exporter Customized Metal Furring Top Hat Profile Ceiling Omega Profile Light Steel Keel Roll Forming Machine Manufacturer

With this motto in mind, we’ve got develop into amongst one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for 8 Years Exporter Customized Metal Furring Top Hat Profile Ceiling Omega Profile Light Steel Keel Roll Forming Machine Manufacturer, We are sincerely wanting forward to creating good cooperative associations with shoppers from in the home and overseas for making a vivid foreseeable future collectively.

With this motto in mind, we’ve got develop into amongst one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for Hat Profile Roll Forming Machine, Our company is an international supplier on this kind of merchandise. We supply an amazing selection of high-quality merchandise. Our goal is to delight you with our distinctive collection of mindful items while providing value and excellent service. Our mission is simple: To supply the best items and service to our customers at the lowest prices possible.

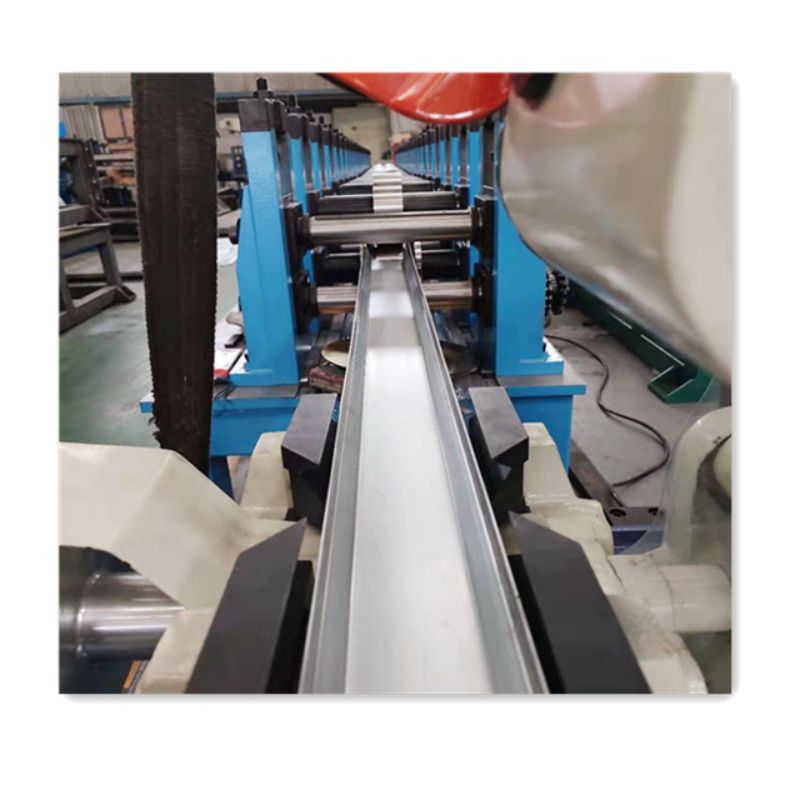

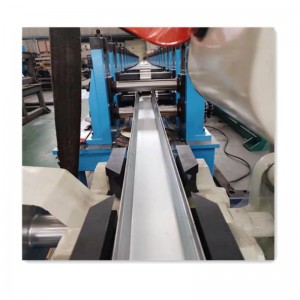

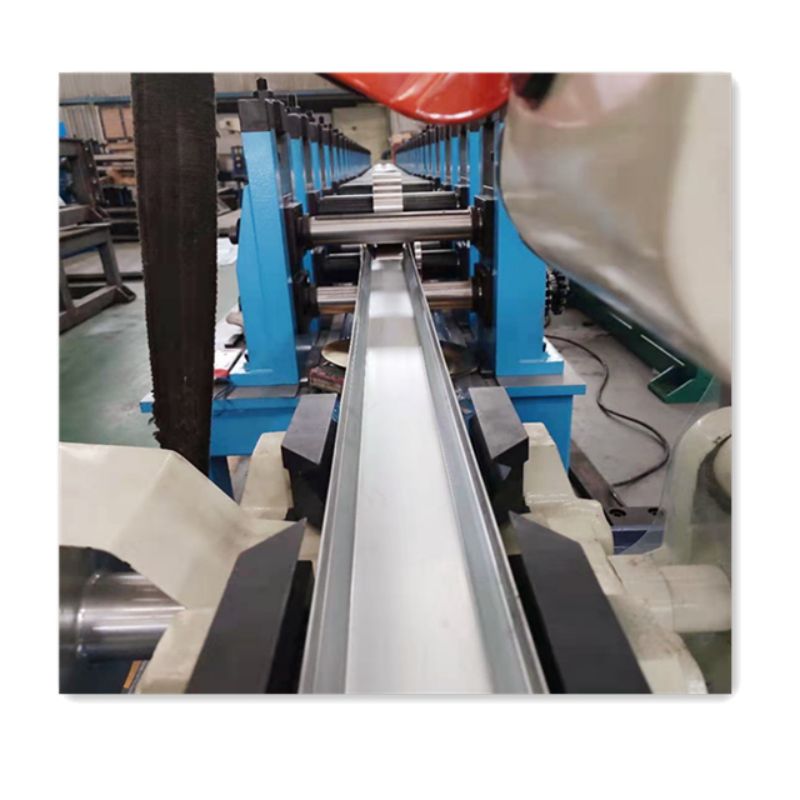

WORKING PRODUCTION

WORKING PRODUCTION:

Uncoiling → leveling → Looper (storage) → servo feeding → Multi-stations punching → forming station →hydraulic cutting → finished product discharging

MAIN PARAMETERS:

| 1 | Machine structure | Individual archway stands structure |

| 2 | Total power | Motor power-18.5kw Hydraulic power-5.5kw |

| 3 | Roller stations | 18 dots stations |

| 4 | Productivity | 15-25m/min |

| 5 | Decoiler | 3T hydraulic decoiler |

| 6 | Leverling part | Upper is 3 rollers, down is 4 stations(total is 7 rollers) |

| 7 | Drive system | By independent gearbox |

| 8 | Diameter of shaft | ¢60mm solid shaft |

| 9 | Roller material | American D2 D3 |

| 10 | Pre punching& cutting system | Pre-cutting to change the material Material of the punching mold: Cr12 |

| 11 | Hydraulic cutting system | Cr12 with heat treatment 58-60° |

| 12 | Hydraulic power | 7.5KW |

SPECIFICATIONS OF COMPONENTS

|

1 |

Automatic De-coiler | 1, Single head design 2, Loading weight: 3Tons 3, Hydraulic automatic expansion and tightening 4, Suitable width: <300mm 5, Coil ID: ¢500±20mm 6, Coil OD: ≤1200mm |

|

2 |

Servo Feeding Leveling |

|

|

3 |

Multi-functional Punching Machine | 1, 6 punching stations, 2, Servo motor power: 1.3KW 3, Servo motor brand: Japan Yaskawa 4, Suitable width: <300mm 5, Punching mold fast positioning, repeat positioning. |

|

4 |

Roll Forming Machine | 1, Driven system: Motor, reducer, spiral bevel gear drive 2, Main machine power: 15KW*2 Sets, 3, Motor brand: SIEMENS BADE servo motor 4, Module Components fast positioning, repeat positioning 5, Forming stations: 18 groups stations |

|

5 |

Hydraulic Cutting Machine | 1, Hydraulic single station, 2, Cutting force: 30Tons, 3, Cutting type: stop cutting 4, Module Components fast positioning, repeat positioning |

|

6 |

Computer Control Box | 1, Japan Mitsubishi motion controller PLC 2, Japan Yaskawa Servo System 3, With human machine interface touch screen 4, Schneider weak current control |

|

7 |

Hydraulic Station | 1,Hydraulic system power: 15KW 2,Hydraulic value: Huade, 3,With fan cooling system |

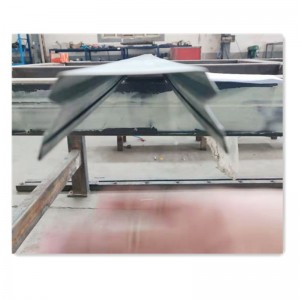

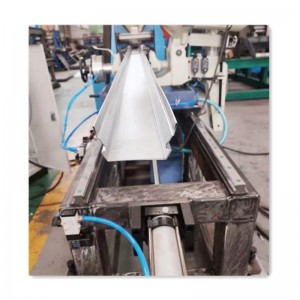

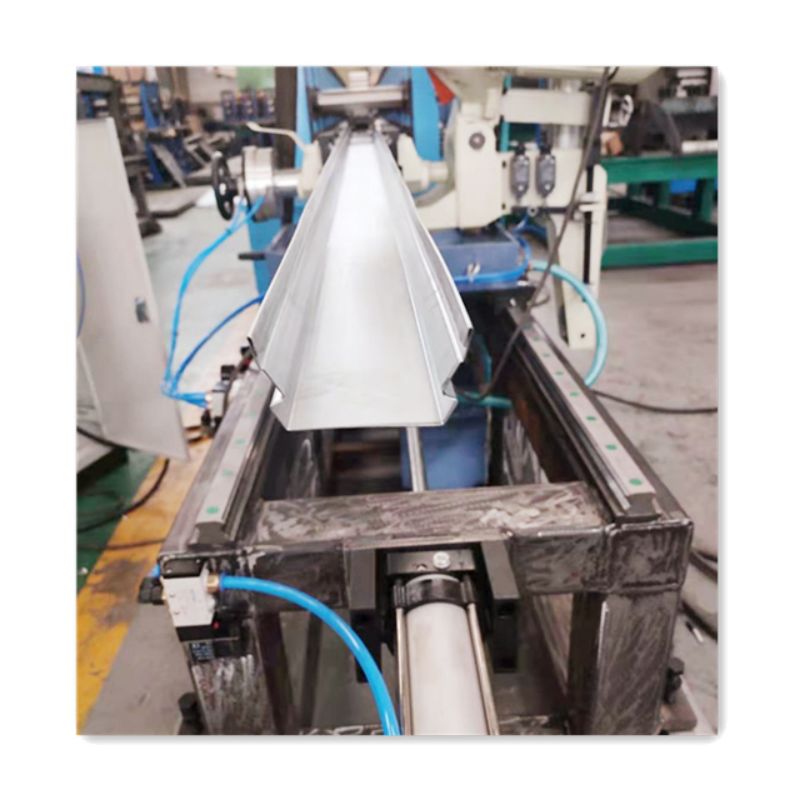

WORKPIECE SAMPLES

A hat shape roll forming machine is a machine used in the metalworking industry to create hat shapes from sheet or coil metal. It is a specialized roll forming machine that utilizes a series of rollers to gradually shape the metal into the desired hat profile.

These machines are commonly used in the construction industry to produce metal studs, track systems and other framing components. Hat Profile Roll Forming Machines feature high precision and high efficiency for consistent, high-quality production of hat profiles.