CE Certificate Automatic Metal Steel Sheet Warehouse Pallet Shelf Storage Rack Cold Roll Forming Machine

“Sincerity, Innovation, Rigorousness, and Efficiency” could be the persistent conception of our organization for that long-term to produce with each other with buyers for mutual reciprocity and mutual gain for CE Certificate Automatic Metal Steel Sheet Warehouse Pallet Shelf Storage Rack Cold Roll Forming Machine, We imagine we are going to become a leader in developing and producing high-quality products and solutions in both Chinese and international markets. We hope to cooperate with more friends for mutual advantages.

“Sincerity, Innovation, Rigorousness, and Efficiency” could be the persistent conception of our organization for that long-term to produce with each other with buyers for mutual reciprocity and mutual gain for China Storage Rack Roll Forming Machine and Cold Roll Forming Machine, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it’s a have to for you of fantastic good quality. Guided by the principle of “Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

MAIN TECHNICAL PARAMETERS

| PLC | Mitsubishi |

| Servo system | Yaskawa, Japan |

| Inverter | Delta (Taiwan, China) |

| Touch screen | Vinylon (Taiwan, China) |

| Low-voltage electrical appliances | Schneider (France) |

| DC speed regulation | Continental (USA) |

| Encoder | Omron (Japan) |

PRODUCTION PROCESS

Uncoiling → Leveling → cold roll forming → Hydraulic Follow → Up cutting → Discharging

MAIN COMPONENTS

The roll forming production line is mainly composed with the following:

Uncoiling machine, leveling machine, roll forming machine, cutting machine, hydraulic station and control station.

The hydraulic station provide the power for the cutting machine, the control station control the forming speed, the control station adopts PLC system with touch screen, the system is capable to read the CAD drawing directly, the operator could also input the product information through touch screen. The roll forming machine make the final product and the cutting machine make the final product to the specific length. The production line equip with individual frame, the frame is capable to adjust based on the size of the product automatically. The PLC system is capable to adjust the speed of the whole production line automatically

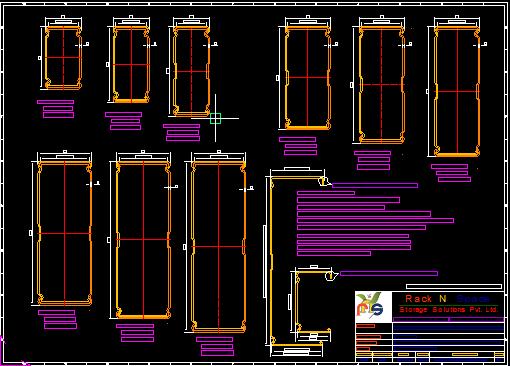

WORKPIECE SAMPLES

APPLICATION

This roll forming production line is used to produce the storage rack cross arms, the arms are widely used in storage warehouse, storage frames; the roll forming production line is capable to produce different size of the cross arms.

Storage shelf beam forming machine is a special equipment for manufacturing storage shelf beams. These machines use the flow forming process to pass a continuous metal strip through a series of rollers that gradually shape it into the desired profile.

A storage rack beam roll forming machine usually consists of several components such as an uncoiler for feeding the metal strip, a leveling unit for straightening the strip, a roller for forming the cutting unit to cut to the desired length Compression molding station. The machine can also include additional features, such as a punching unit for punching holes or slots in beams. These machines are designed to handle different types of materials, such as steel or aluminum, and can accommodate storage rack beams of various sizes and profiles. They are commonly used in industries such as warehousing, logistics, and manufacturing, where storage shelves are essential for organizing and storing products.

By using storage rack beam roll forming machines, manufacturers can efficiently produce high-quality beams with consistent dimensions and precise contours. The technique minimizes material waste and reduces labor requirements, offering cost-saving advantages over traditional manufacturing methods.