China OEM Light Gauge Steel Framing Purlin Roll Forming C Channel Z U Roll Former Machine

“Sincerity, Innovation, Rigorousness, and Efficiency” may be the persistent conception of our organization for that long-term to establish jointly with customers for mutual reciprocity and mutual gain for China OEM Light Gauge Steel Framing Purlin Roll Forming C Channel Z U Roll Former Machine, You should really don’t hesitate to call us for anyone who is fascinated within our items. We firmly feel our solutions will make you contented.

“Sincerity, Innovation, Rigorousness, and Efficiency” may be the persistent conception of our organization for that long-term to establish jointly with customers for mutual reciprocity and mutual gain for China Steel Purlin Roll Forming C Channel Z U Roll Former Machine, We have got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

Production Description

Main Parameters:

1. Plate thickness: 1.0-3.5mm, 2.5mm for inspection

2. Material: Aluminum zinc plate

3. Coil outer diameter: Ф 1200 mm

4. Coil inner diameter: Ф 508mm

5. Width of steel strip: < 650mm

6. Single roll weight: ≤ 5000 kg

7. Power requirements: 380V, 50Hz, 3-phase

8. Effective working speed of the whole line: 15 ~ 20m / min

Production process

The production line is carried out according to the following technological process:

Uncoiler → leveler → looper (material storage)→ servo feeding → multi-station punching machine (cut off)→ molding main machine → finished product discharge

Product Detail

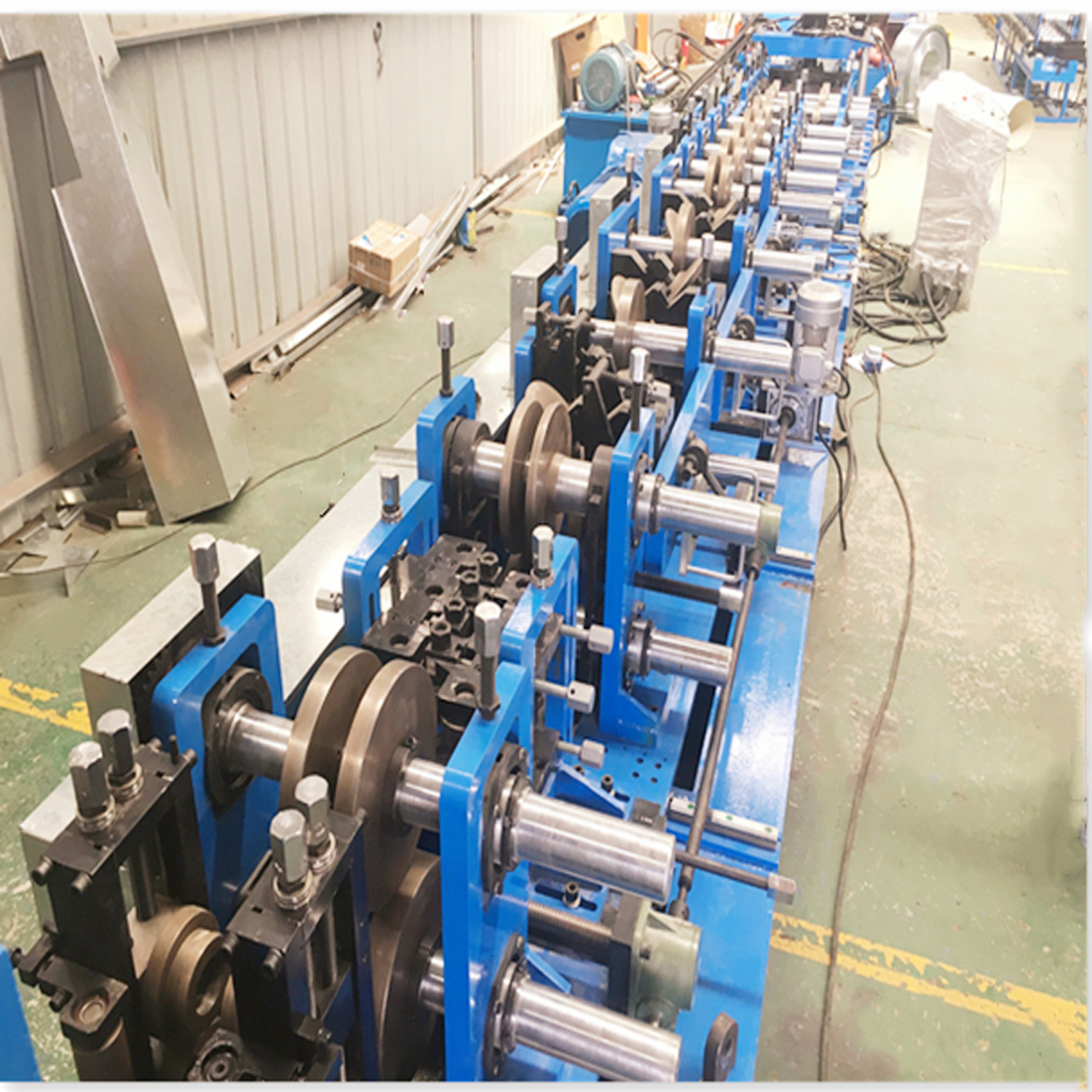

Main forming machine

(1)Main frame material:400# steel, thickness of Middle plate is 25mm. The main frame of machine is welded separately and the outside wall is connected by screw after being shot blasted on

the surface. there are two purpose of being shot blasted: one, derusting. Two surface strengthening.

(2)Number of forming steps:15steps, Roller fixer: Middle plate welded

(3)Roller material:Cr15 steel with quenching, The rollers are plated with hard chrome with thickness of 0.05mm on the surface after being machined by the exact machine tool. So that ensure long life of forming rollers. and we use separate rollers for whole line

(4)Shaft material:45#steel ,Diameter:80mm, Shafts of rollers are tooled by grinding machine for two times to ensure time forever

(5)Transmission style: chain, 2 inch , Chain and gear move the line, motor drives. (6)Voltage:380v50hz3p or as your request

(7)Main motor power:15kw

(8) Safety cover: Available

Leveling machine

(1)Function: Pull and feed material into machine, which make whole line working smoothly and accurate.

(2)Electric drive with motor

(3)Five step flattening rollers

PLC control box

(1)Brand: Delta

(2)Frequency transformer: Delta

(3)Reducer: Chinese famous brand

(4)5.7inch touch operate screen

(5)Counter: Chint

(6)Operate language: English and Chinese

Punching machine

(1)Separate hydraulic powered punching device on machine

(2)Punching speed can be adjusted easily by servo motor

(3) One pcs punching mold for all sizes

Cutting system

(1) Adopts post cutting, no limited cutting mode, no need change cutting blade for all sizes .advanced hydraulic drive, automatic cutting after forming, no

distorting or wasting, high level safety factor.

(2)Cutting mold:Cr12 with heat treated

(3)Cutting length tolerance ±1mm. The power of cutting is provided by hydraulic station

(4)The final product can be cut as per set length in PLC controller, and the length is automatically measured by encoder.

Hydraulic pump

(1)1 set ,with power 5.5kw

(2)Include a set of hydraulic tank , a set of hydraulic oil pump, four hydraulic pipes(It supplies the power for the hydraulic punching and cutting). And three sets of electromagnetism valves

Simple run out table

(1)1 pieces, welded by 60*40mm square steel pipe, size 6 meters

(3)The height can be adjusted, we can also design as your special requestA C U Z steel purlin forming machine is a kind of equipment used in the manufacturing process of C-shaped, U-shaped and Z-shaped steel purlins. Purlins are structural components used in building construction to provide additional support for roofs and walls.

Roll forming machines take flat steel strip and form it into the desired shape, whether it is a C, U or Z profile. It uses a series of rollers and tools to gradually bend and shape the strip. The machine usually consists of a decoiler for securing and feeding the strip, a leveler for straightening the strip and various forming stations for forming the final purlin shape.

C U Z purlin roll forming machines are essential for the efficient and accurate production of purlins, resulting in consistent quality and high productivity.