High Quality Wholesale Direct Factory Price PPGI PPGL Metal Double Galvanized Roofing Steel Floor Deck Cold Roll Forming Machine Mexico

Our company insists all along the quality policy of “product quality is base of enterprise survival; customer satisfaction is the staring point and ending of an enterprise; persistent improvement is eternal pursuit of staff” and the consistent purpose of “reputation first, customer first” for High Quality Wholesale Direct Factory Price PPGI PPGL Metal Double Galvanized Roofing Steel Floor Deck Cold Roll Forming Machine Mexico, We also make sure that your assortment will be crafted while using the optimum quality and dependability. Make sure you experience totally free to make contact with us for more information and facts.

Our company insists all along the quality policy of “product quality is base of enterprise survival; customer satisfaction is the staring point and ending of an enterprise; persistent improvement is eternal pursuit of staff” and the consistent purpose of “reputation first, customer first” for China Roll Forming Machine and Floor Decking Roll Former, We aim to become the modern enterprise with the commercial ideal of “Sincerity and confidence” and with the aim of “Offering customers the most sincere services and best quality products”. We sincerely ask for your unchanged support and appreciate your kind advice and guidance.

PRODUCT APPLICATION

MAIN TECHNICAL PARAMETERS

Material: Galvanized cold-rolled sheet

Yield strength of raw materials: ≤275Mpa

Tensile strength of raw materials: ≤550Mpa

Coil OD: ≤Ф1300 mm

Coil ID: Ф508

Strips width: ≤1450mm

Strips thickness: 0.8~1.2mm

Coil weight: ≤10000 kg

MAIN COMPOSITIONS

| No | Items Name | Specifications |

| 1 | Decoiler | Single head mode, single support; Coil ID: Ф508; Coil OD: Ф1300mm; Strips width: 1450 mm; Max. Weight: ≤10000 kg |

| 2 | Roll Forming Machine |

Structure: the forming unit is driven by motor reducer chain; Forming stations:36 stations; Forming machine shaft dia:φ95mm; Motor power: 22kwX2; Max: 15m/min |

| 3 | Hydraulic Cutting | The cutter mode adopts blanking shearing; Blade material: Cr12MoV (hardness after quenching HRC58~62); Parameter: cutting accuracy:±1.5mm |

| 4 | Electrical Control Cabinet |

Main electrical components; PLC: Mitsubishi; Inverter: delta ; Touch screen: veron (Taiwan, China) ; Low-voltage electrical appliances: schneider (France) ; Encoder: Omron (Japan) |

| 5 | Hydraulic System | Hydraulic system USES filter, the cleanliness of oil to ensure 6-8 grade |

| Run-out Table | Size: 3*1.2*0.6m; Adjustable Height |

PRODUCTION PROCESS

Uncoling → Flatterning → Roll Forming → Dischaging

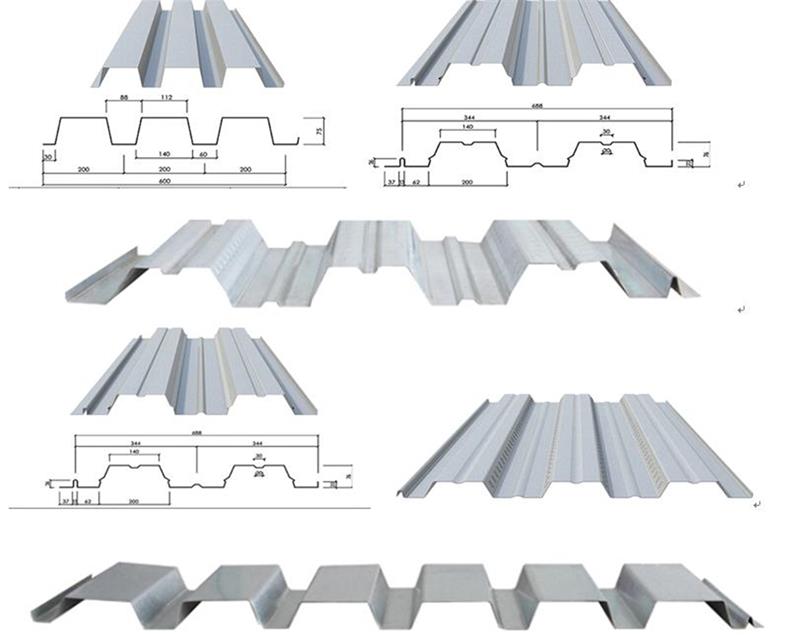

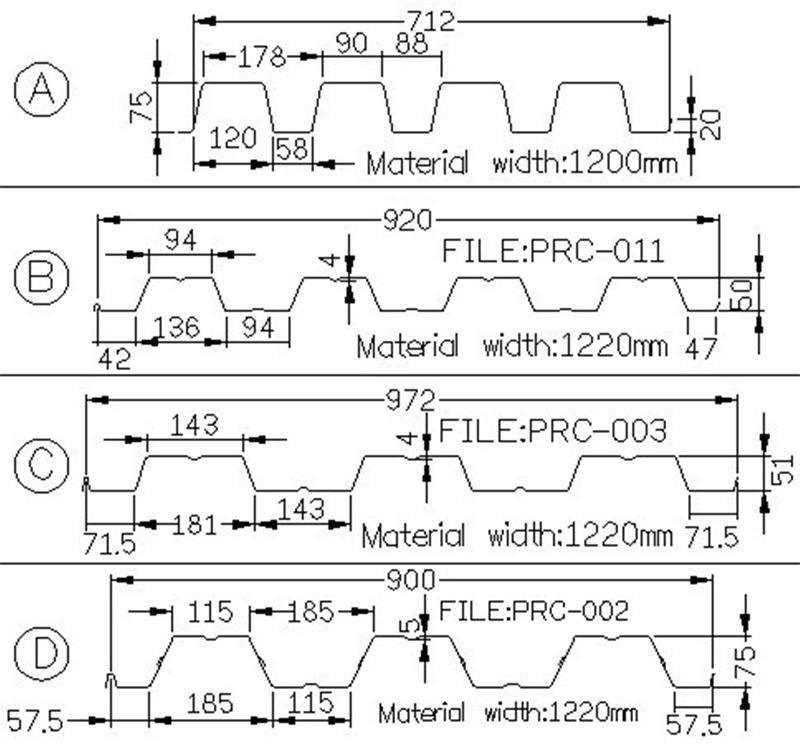

WORKPIECE SAMPLES

Metal decking is corrugated metal sheeting that’s used as a structural roof deck or composite floor deck. It will be supported by steel beams or joists The purpose of metal deck is to support the insulating membrane of a roof or to support and bond with the concrete to create a composite metal floor deck.

The floor forming machine is a special equipment for the production of floor slabs in the construction industry. It is designed to convert metal coils into homogeneous, high-quality floor finish profiles in a continuous process.

The machine works by feeding coils of metal through a series of rollers and forming stations.

Floor roll forming machines offer several advantages in floor production, including high efficiency, precision and cost-effectiveness. It enables manufacturers to produce high volumes of floor trim panels with consistent quality and dimensional accuracy. Overall, floor roll forming machines play a vital role in streamlining the production process and meeting the flooring demands of the construction industry.