Europe style for Metal Shelf Storage Rack Beam Forming Machinery Storage Shelf Cold Roll Forming Machine

Our products are widely regarded and trustworthy by customers and might meet constantly changing financial and social demands for Europe style for Metal Shelf Storage Rack Beam Forming Machinery Storage Shelf Cold Roll Forming Machine, We sincerely hope to provide both you and your organization with a superior start. If there is anything we will do to suit your needs, we shall be more than pleased to do so. Welcome to our manufacturing facility for take a look at.

Our products are widely regarded and trustworthy by customers and might meet constantly changing financial and social demands for China Metal Shelf Storage Rack Beam Forming Machinery and Storage Shelf Roll Forming Machine, So far our products have been exported to east Europe, the Middle East, Southeast, Africa and South America etc. We have 13years professional sales and purchase in Isuzu parts at home and abroad and the ownership of the modernized electronic Isuzu parts checking systems. We honor our core principal of Honesty in business, priority in service and will do our best to offer our customers with high quality products and excellent service.

MAIN TECHNICAL PARAMETERS

| PLC | Mitsubishi |

| Servo system | Yaskawa, Japan |

| Inverter | Delta (Taiwan, China) |

| Touch screen | Vinylon (Taiwan, China) |

| Low-voltage electrical appliances | Schneider (France) |

| DC speed regulation | Continental (USA) |

| Encoder | Omron (Japan) |

PRODUCTION PROCESS

Uncoiling → Leveling → cold roll forming → Hydraulic Follow → Up cutting → Discharging

MAIN COMPONENTS

The roll forming production line is mainly composed with the following:

Uncoiling machine, leveling machine, roll forming machine, cutting machine, hydraulic station and control station.

The hydraulic station provide the power for the cutting machine, the control station control the forming speed, the control station adopts PLC system with touch screen, the system is capable to read the CAD drawing directly, the operator could also input the product information through touch screen. The roll forming machine make the final product and the cutting machine make the final product to the specific length. The production line equip with individual frame, the frame is capable to adjust based on the size of the product automatically. The PLC system is capable to adjust the speed of the whole production line automatically

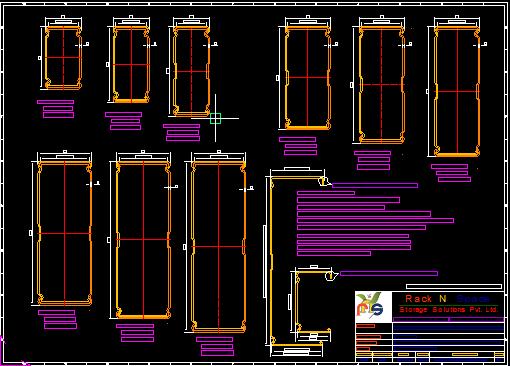

WORKPIECE SAMPLES

APPLICATION

This roll forming production line is used to produce the storage rack cross arms, the arms are widely used in storage warehouse, storage frames; the roll forming production line is capable to produce different size of the cross arms.

Storage shelf beam forming machine is a kind of equipment that manufactures storage shelf beams by rolling forming process. Roll forming is a continuous bending operation in which a long metal strip is passed through a continuous set of rollers, gradually forming it into the desired shape.

Storage shelf beam forming machine usually consists of uncoiler, leveler, forming machine, cutting system and control system. The uncoiler feeds the metal strip into the machine, while the leveler ensures that the strip is flat and even. A roll former then shapes the strip to the exact profile required for the storage rack beams. The cutting system trims the beams to the desired length and the control system manages the entire operation and setup. These machines are designed to produce storage rack beams in different sizes and profiles according to the specific requirements of the project.

The roll forming machine has the characteristics of high efficiency and high precision, and is often used to manufacture various metal products, including storage shelves, beams, shelves, etc.

Overall, the storage rack beam forming machine is a cost-effective solution for high-volume production of high-quality storage rack beams to meet the needs of the storage industry.