Big discounting Standing Seam A2 Roof Deck Plate Selflock Roofing Sheet Cold Bending Roll Forming Machine Price

We support our consumers with ideal top quality products and higher level services. Becoming the specialist manufacturer in this sector, we have now obtained prosperous practical working experience in producing and managing for Big discounting Standing Seam A2 Roof Deck Plate Selflock Roofing Sheet Cold Bending Roll Forming Machine Price, “Quality initially, Price tag least expensive, Company best” may be the spirit of our organization. We sincerely welcome you to definitely visit our firm and negotiate mutual organization!

We support our consumers with ideal top quality products and higher level services. Becoming the specialist manufacturer in this sector, we have now obtained prosperous practical working experience in producing and managing for China Roll Forming Machine and Tile Making Machine, When you are keen on any of our objects following you view our product list, please feel free to make contact with us for inquiries. You’ll be able to send us emails and get in touch with us for consultation and we shall respond to you as soon as we have been able to. If it’s convenient, you could find out our address in our web site and come to our enterprise. or additional information of our products by yourself. We’re generally ready to build lengthy and steady co-operation relations with any possible shoppers within the associated fields.

MAIN TECHNICAL PARAMETERS

MAIN PARAMETERS:

| No | Items Name | Specification |

| 1 | Material | galvanized cold rolled sheet |

| 2 | Yield strength | ≤550Mpa |

| 3 | Tensile strength | ≤650Mpa |

| 4 | Coil OD | ≤Ф1300 mm |

| 5 | Coil ID | Ф508mm |

| 6 | Coil input width | 800mm |

| 7 | Steel Strip width | ≤1450mm |

| 8 | Steel Strip thickness | 0.4~0.7mm |

| 9 | coil weight | ≤6000 kg |

WORKING PROCESS:

uncoiler→ guiding feeding→ feeding→ cutting to length→ roll forming→ finished products discharging

TECHNICAL SPECIFICATIONS:

1.Main motor reducer: motor power: 5.5kw

2.Cycloid gear reducer: bwd27-43-5.5kw

3.Drive chain sprocket:Chain models:16A-1, sprocke model:16A15Z,Material;45# steel, high frequency quenching of tooth tip

3. Frame structure of main machine :300 channel steel is welded, one end is fixed, the other end is moved as a whole

4. Integrated wall panel: A3(individual archway stands is optional)

5. Welding material: advanced flux-cored welding wire is adopted. The strength and other mechanical properties of the frame and structural parts are equivalent to those of the ship components

6. Roller material :45# steel, precision rolling, roll surface plating hard chrome all roll keyway cutting, install key pin

7. Main shaft material :45# steel, fine car, shaft diameter: 70mm, all spindle cutting keyway, install key pin

8. Blade material :Cr12,fine machining,quenching:HRC58-62°,wire cutting, fine grinding

9. sleeve :45# seamless steel tube,lathe finishing,Ensure dimensions and parallelism,Blackening of the surface

10.Bearing :Model:6210 etc,Origin:HRB

11.Frame stations:19

12.Forming stations:.18

13.line speed :0-15m/min

14.Overall size:6.8m×1.0m×1.5m

15.Rolling thickness:0.5-0.8mm

16.Cutting accuracy :10m±2mm

MAIN ELECTRICAL COMPONENTS

| No | Items Name | Brand |

| 1 | Transducer | Yaskawa |

| 2 | PLC | Panasonic |

| 3 | Operation screen | MCGS |

| 4 | Low volatge components | Schneider |

| 5 | Encoder | Omron |

| 6 | hydraulic station power | Beijing Huade |

| 7 | hydraulic valve | Beijing Huade |

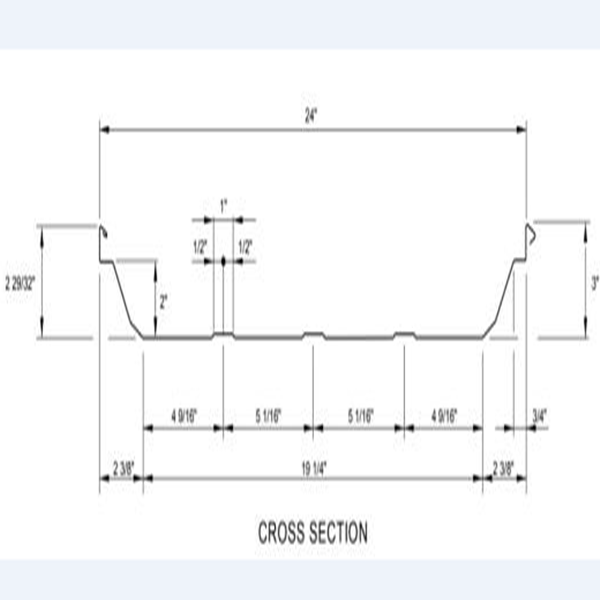

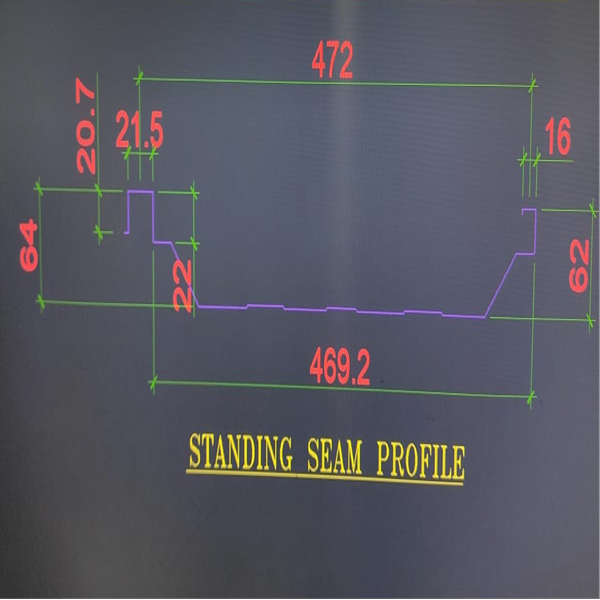

WORKPIECE SAMPLES

Standing seam roof roll forming machine is a type of equipment used in the roofing industry to manufacture standing seam roofs.

It is designed for the efficient and accurate production of standing seam roof panels by continuous rolling and forming of sheet metal. The machine usually consists of a series of rollers and stands that guide the sheet metal through the roll forming process.

As the sheet passes through the rollers, it undergoes various bending and forming operations. These operations create a standing seam profile, which features raised ribs or seams that interlock when the panels are installed on the roof.

The roll forming process is highly automated and can be custom produced in different widths, lengths and profiles for standing seam panels. Some advanced machines may also have additional features such as computer controls, automatic shearing systems, and material handling systems to increase productivity.

Standing seam roofing roll forming machines are widely used in commercial and residential construction projects due to their speed, precision and versatility. They can produce high quality standing seam roofs that are durable, weather resistant and aesthetically pleasing.