Factory Cheap Roll up Door Panel Shutter Forming Machine Roller Shutter Door Roll Forming Machine

To be the stage of realizing dreams of our employees! To build a happier, extra united and extra professional team! To reach a mutual reward of our shoppers, suppliers, the society and ourselves for Factory Cheap Roll up Door Panel Shutter Forming Machine Roller Shutter Door Roll Forming Machine, Our closing purpose is “To try the most beneficial, To generally be the Best”. Be sure to sense free of charge to get hold of with us if you have any prerequisites.

To be the stage of realizing dreams of our employees! To build a happier, extra united and extra professional team! To reach a mutual reward of our shoppers, suppliers, the society and ourselves for China Roll up Door Forming Machine and Door Roll Forming Machine, Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

MAIN TECHNICAL PARAMETERS

Allowable coil ID: Ф508

Maximum allowable roll diameter: Ф1500mm

Maximum allowable roll width: 200 mm

Maximum roll carrying weight: ≤2000 kg

Archway material: QT450.

Roller shaft material: 40Cr, quenched and tempered, hardness is HRC45~50

Parameters: Forming passes: 14 passes (subject to the final design)

Shaft diameter of forming machine: φ50mm (subject to final design)

Motor power: 5kw DC motor (Nanyang or Ace)

Maximum linear speed: 2~8m/min

MAIN COMPONENTS

3.1 2 ton single head unpowered decoiler 1 set

Uncoiling: The machine is in single-head mode. Single support, manually fix the material roll on the uncoiler material shaft.The working condition is stable and reliable.

3.2 Feeding Guide 1set

Feeding guide, reasonable design, can be fixed on one side and movable on the other side, the screw rod is adjusted, and the position display shows the scale.

The guide plates on both sides of the plate are heat treated to ensure the hardness.

3.3 Precision roll forming unit 1set

There are two types of nuts on the outside of the archway: left-handed (lower shaft) and right-handed (upper shaft).

3.4 Hydraulic Shearing:

Stop shearing, cutting adopts blanking cutting to ensure the integrity of the arc part.

3.5 Electrical control system:

| No | Item Name | Brand |

| 1 | PLC | Schneider |

| 2 | Inverter | Schneider |

| 3 | Low-voltage electrical appliances | Schneider |

| 4 | Encoder | Schneider/Omron |

| 5 | Touch screen | Vinylon |

3.6 Hydraulic System:

The hydraulic system is a fast hydraulic system, suitable for high-speed punching, perforating rolls and shearing cold bending production lines. The main hydraulic components adopt Beijing Huade products.

The main components are: oil pump, motor, hydraulic valve, solenoid valve, filter and hydraulic tank,

The hydraulic system adopts a filter, and the cleanliness of the oil is guaranteed to be level 6-8.

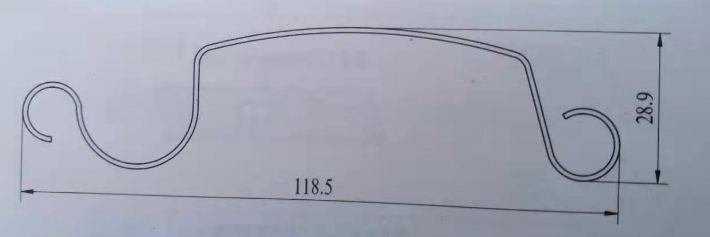

WORKPIECE SAMPLES

Roller shutter door roll forming machine; roller shutter door making machine; rolling shutter door machine.

Rolling Shutter Door Roll Forming Machine for Sale can be designed to product different shapes and sizes according to the customers’ requirments. And its speed is high, which improves its productivity greatly. Besides, Its products are always high quality and fashionable styles. It is widely used in nowadays.