Hot New Products PLC Control Galvanized Stainless Steel E Style Cable Tray Cable Ladder Roll Former Equipment

Our objective is to present premium quality products at aggressive prices, and top-notch services to buyers around the world. We have been ISO9001, CE, and GS certified and strictly adhere to their excellent specifications for Hot New Products PLC Control Galvanized Stainless Steel E Style Cable Tray Cable Ladder Roll Former Equipment, It is our wonderful honor to satisfy your needs.We sincerely hope we are able to cooperate along with you from the in the vicinity of future.

Our objective is to present premium quality products at aggressive prices, and top-notch services to buyers around the world. We have been ISO9001, CE, and GS certified and strictly adhere to their excellent specifications for China Cable Tray and Roll Forming Machine, We welcome you to visit our company, factory and our showroom displayed various items that will meet your expectation, meanwhile, it is convenient to visit our website, our sales staff will try their efforts to provide you the best service. If you want more information, remember to do not hesitate to contact us by E-mail or telephone.

PRODUCTION DESCRIPTIONA

This cable tray production line is a specially equipment for cable tray roll forming,also can finish the production of its cover plate, which widely applicable in power transmission, machinery and equipment, commercial buildings and other facilities, including computer rooms, parking lots, data centers, offices, Internet service providers, hospitals, schools/universities, airports and factories, etc.

MAIN TECHNICAL PARAMETERS

| No | Model: SART-1250*2.5 | Specification |

| 1 | Material | CR/HR/G. I steel |

| 2 | Coil OD | Ф1200 mm |

| 3 | Coil ID | Ф508mm |

| 4 | Strips width | <1250mm |

| 5 | Strips Thickness | 0.5~2.5mm |

| 6 | Cable Tray Width | 100~800mm |

| 7 | Cable Tray Height | 50~200mm |

| 8 | Coils weight | ≤10000 kg |

| 9 | Electrical power | 415V,50Hz,3phase |

| 10 | Line Speed | 5~15m/min |

MAIN COMPONENTS

This production line is mainly composed by following parts:

1. Uncoiler. 1 set

Single support,four-bar tension structure, tension force comes from hydraulic cylinder, adjustment is fast and reliable.

2. Leveler. 1 set

It adopts 7 rollers for leveling, 2 pairs of guide rollers, feed rollers are pneumatically clamped, frequency conversion speed regulation, switch control.

3. Looper ( Storage Material) 1 set

Used to buffer the speed mismatch between the unwinding and leveling and the punching machine, and correct the deviation;

4. Servo Feeder. 1 set

The sheet is fed in according to the actual step length required for punching, and multiple sets of feeding parameters can be set at one time, which is convenient and quick.

5. Multi-stations Punching&Cutting Unit 1 set

It adopts liquid four-column press mode, which is economical, applicable and fast. The punching machine has a 6-station punching mode and contains 3 to 4 sets of die sets, which can continuously punch out multiple types of holes.

6. Cantilever adjustable forming machine 1 set

The forming unit adopts the cantilever forming machine mode. Motor, reducer, spiral bevel gear drive.When producing products with different bottom widths and waist heights, you only need to set the parameters on the touch screen, which is convenient, fast and reliable.

PRODUCTION PROCESS

Uncoiler → Leveler → Loop (storage) → Sevo Motor → multi-stations punching machine(cutting)→ Finished Products

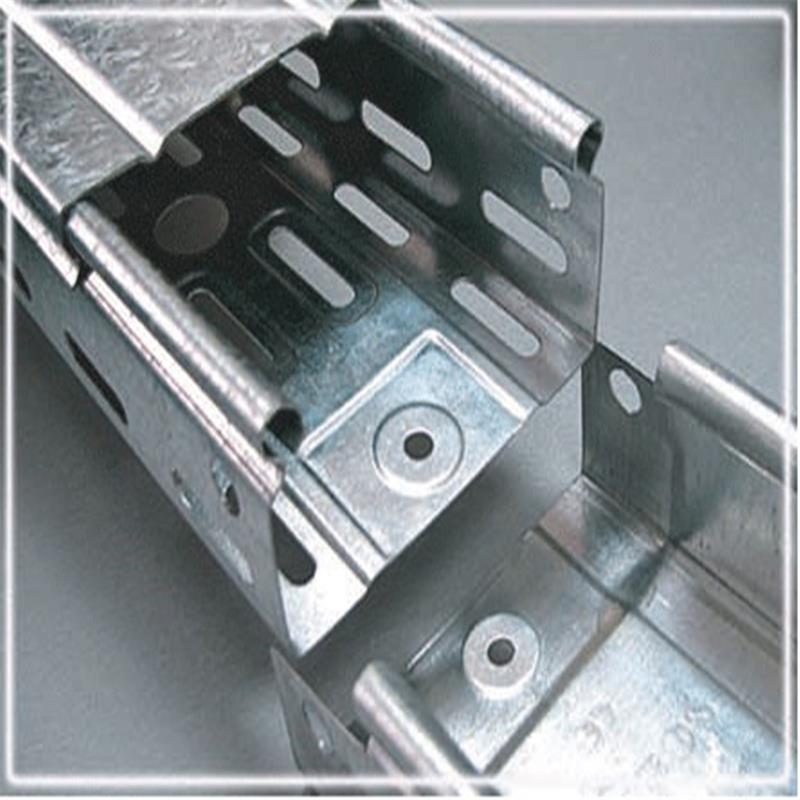

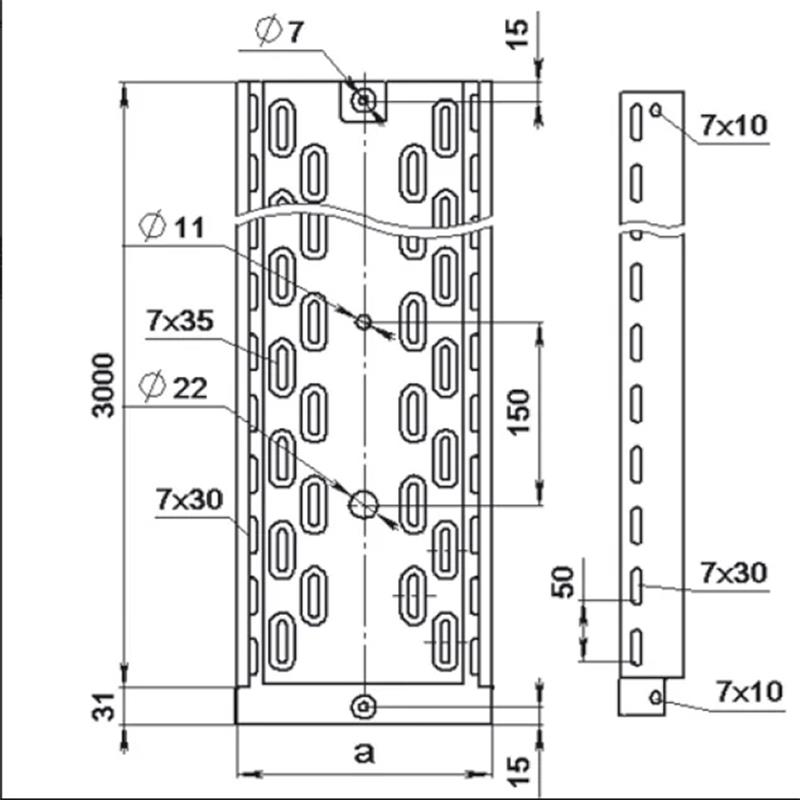

WORKPIECE SAMPLES

Cable tray roll forming machine / cable bridge making machine / electrical cable tray forming production line / cable cover making machine / cable tray making machine / able bridge roll forming production line.

Cable tray roll forming machine uses cantilever type at the two sides, the punch press do the round ribs in bottom or different holes’stamping and cutting.

The material is guided into main roll forming machine by guider. By electrical control, automatically improve and adjust different width and height.