Factory Outlets Metal Garage Steel Rolling up Roller Shutter Door Profile Roll Forming Machine

Our development depends on the advanced equipment, excellent talents and continuously strengthened technology forces for Factory Outlets Metal Garage Steel Rolling up Roller Shutter Door Profile Roll Forming Machine, We are sincerely looking forward to cooperate with buyers all around the world. We imagine we will satisfy you. We also warmly welcome shoppers to visit our organization and purchase our merchandise.

Our development depends on the advanced equipment, excellent talents and continuously strengthened technology forces for China Roll Forming Machine and Tile Making Machine, “Good quality and reasonable price” are our business principles. If you are interested in our items or have any questions, you should feel free to contact us. We hope to establish cooperative relationships with you in the near future.

MAIN TECHNICAL PARAMETERS

Allowable coil ID: Ф508

Maximum allowable roll diameter: Ф1500mm

Maximum allowable roll width: 200 mm

Maximum roll carrying weight: ≤2000 kg

Archway material: QT450.

Roller shaft material: 40Cr, quenched and tempered, hardness is HRC45~50

Parameters: Forming passes: 14 passes (subject to the final design)

Shaft diameter of forming machine: φ50mm (subject to final design)

Motor power: 5kw DC motor (Nanyang or Ace)

Maximum linear speed: 2~8m/min

MAIN COMPONENTS

3.1 2 ton single head unpowered decoiler 1 set

Uncoiling: The machine is in single-head mode. Single support, manually fix the material roll on the uncoiler material shaft.The working condition is stable and reliable.

3.2 Feeding Guide 1set

Feeding guide, reasonable design, can be fixed on one side and movable on the other side, the screw rod is adjusted, and the position display shows the scale.

The guide plates on both sides of the plate are heat treated to ensure the hardness.

3.3 Precision roll forming unit 1set

There are two types of nuts on the outside of the archway: left-handed (lower shaft) and right-handed (upper shaft).

3.4 Hydraulic Shearing:

Stop shearing, cutting adopts blanking cutting to ensure the integrity of the arc part.

3.5 Electrical control system:

| No | Item Name | Brand |

| 1 | PLC | Schneider |

| 2 | Inverter | Schneider |

| 3 | Low-voltage electrical appliances | Schneider |

| 4 | Encoder | Schneider/Omron |

| 5 | Touch screen | Vinylon |

3.6 Hydraulic System:

The hydraulic system is a fast hydraulic system, suitable for high-speed punching, perforating rolls and shearing cold bending production lines. The main hydraulic components adopt Beijing Huade products.

The main components are: oil pump, motor, hydraulic valve, solenoid valve, filter and hydraulic tank,

The hydraulic system adopts a filter, and the cleanliness of the oil is guaranteed to be level 6-8.

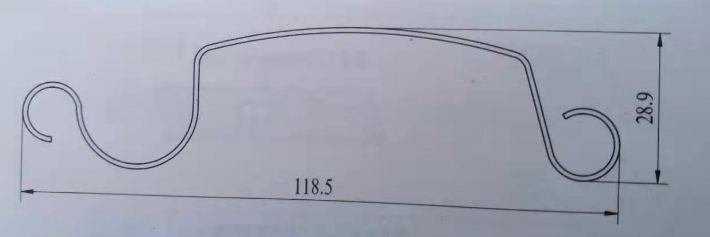

WORKPIECE SAMPLES

Roller shutter door roll forming machine; roller shutter door making machine; rolling shutter door machine.

Rolling shutter door forming machine is a kind of machinery used to manufacture rolling shutter doors. It is designed to perform roll forming, in which a continuous metal strip is fed into a station where it is gradually formed into the desired profile for a rolling door.

The machine typically includes a series of rollers, guides and cutting systems to achieve precise and consistent results. Roller doors are commonly used for security and access control in industrial and commercial environments. Roll forming machines can produce these doors in high volumes with customizable features such as size, color and material. It can produce doors in various profiles, including slatted doors and perforated designs.

These machines are usually used by manufacturers or companies involved in the production of rolling doors. They can be operated manually or automatically, depending on the specific machine and its capabilities.

Before investing in a rolling door forming machine, it is important to consider factors such as the desired door profile, production capacity and specific requirements.