Factory Promotional Azerbaijan Steel Glazed Tile Cold Roll Roof Forming Construction Machinery

we can easily provide top quality solutions, competitive value and best client company. Our destination is “You come here with difficulty and we provide you a smile to take away” for Factory Promotional Azerbaijan Steel Glazed Tile Cold Roll Roof Forming Construction Machinery, We’re on the lookout ahead to building positive and valuable links using the providers across the planet. We warmly welcome you to definitely get hold of us to begin discussions on how we will bring this into being.

we can easily provide top quality solutions, competitive value and best client company. Our destination is “You come here with difficulty and we provide you a smile to take away” for China Roof Panel Roll Forming Machine and Roofing Sheet Making Machine, We adopted technique and quality system management, based on “customer orientated, reputation first, mutual benefit, develop with joint efforts”, welcome friends to communicate and cooperate from all over the world.

PRODUCT DESCRIPTION

This glazed tile roll forming machine is used for making the glazed tile,which is widely used in factories, houses, hotels, villas and other industrial and civil buildings.

MAIN PARAMETERS

Material: Galvanized sheet

Yield strength of raw materials: ≤235Mpa

Tensile strength of raw materials: ≤550Mpa

Outer Diameters of Coils: ≤Ф1300 mm

Inner Diameter of Coils: Ф508

Steel strap width: ≤1000mm

Steel Strap Thickness: 0.2~0.4mm

Weight/Coil: ≤5000 kg

PRODUCTION PROCESS

The glazed tiles manufacturing machine products are carried out according to the following process:

Uncoiling → Looper (Storage) → Cold Forming → Pressing Table & Cutting → Discharging

MAIN COMPONENTS&SPECIFICATION

| No | Items Name | Specifications |

| 1 | Decoiler | Manual Type; Coils ID: Ф508mm; Coil OD: Ф1300mm; Coil Width: 1000mm; Coil weight: ≤5000 kg |

| 2 | Roll Forming Machine | The forming unit is driven by motor, reducer and sub-reducer. Molding machine memorial arch for independent memorial arch structure (non – plate structure), stable performance, reliable, high precision. The base is welded steel structure. Annealing after welding.The molding roller is designed by professional software, and the material is made of high quality 45 steel and hard chrome plating. Forming passes: 16 passes (subject to the final design); Shaft diameter: φ70mm (subject to final design); Motor power: 5.5kw Maximum linear speed: 2~5 m/min |

| 3 | Hydraulic Cutting | Cutter mode adopts no scrap cutting. Cutter material: Cr12MoV (hardness is HRC58~62 after quenching); Measuring accuracy: ±1.5mm |

| 7 | Electrical Control Cabinet | PLC: Mitsubishi; Inverter: Delta; Touch screen: Vinylon (Taiwan, China); Low-voltage electrical appliances: Schneider (France); Encoder: Omron (Japan) |

| 8 | Hydraulic System | Hydraulic system USES filter, the cleanliness of oil to ensure 6-8 grade |

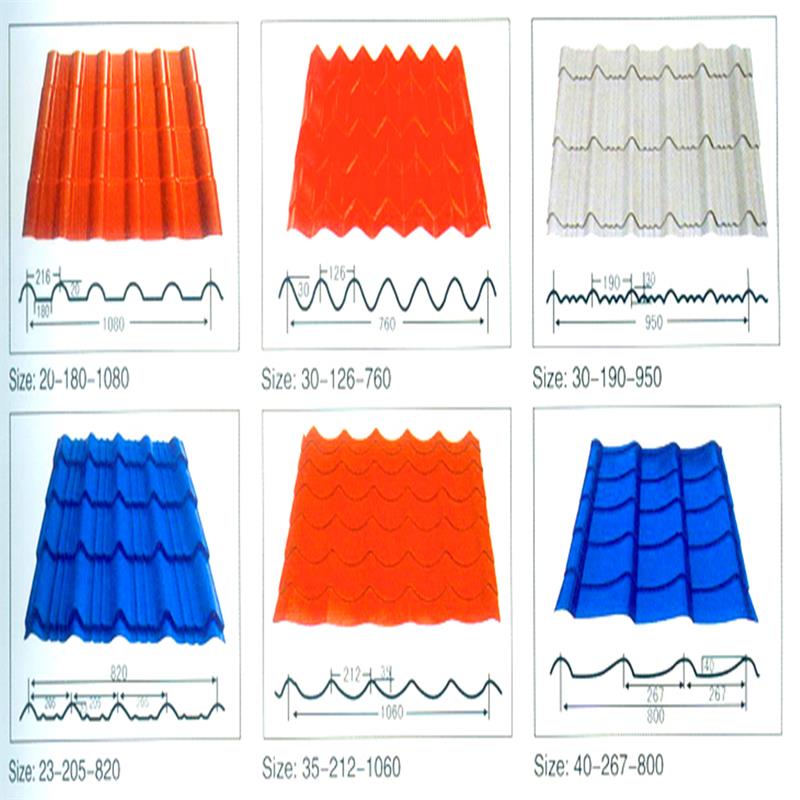

WORKPIECE SAMPLES

Glazed tile roll forming machine;glazed tiles manufacturing machine;glazed tile forming machine

Glazed tile forming machine is the equipment used to manufacture and produce glazed tiles. It is designed to shape metal coils and form the desired profile of glazed tiles. The machine usually consists of a series of rollers and forming stations that work together to gradually shape the metal coil. The rollers apply pressure to the metal coil, gradually bending and shaping it into the correct contour.

The machine also includes a cutting mechanism for cutting the metal coil into individual tiles of desired length.

Additionally, some machines may include features such as control panels and computer systems for precise operation and monitoring. Glazed tile roll forming machine is an essential tool in glazed tile production, which improves the efficiency and accuracy of the manufacturing process.