Factory supplied Shelves Rack Pillar Beam Upright Roll Forming Machine Rack Shelf Box Beam Roll Forming Machinery

Our rewards are reduce selling prices,dynamic revenue team,specialized QC,sturdy factories,superior quality services for Factory supplied Shelves Rack Pillar Beam Upright Roll Forming Machine Rack Shelf Box Beam Roll Forming Machinery, “Making the Products of Significant Quality” will be the eternal objective of our business. We make unremitting attempts to notice the purpose of “We Will Always Preserve in Pace together with the Time”.

Our rewards are reduce selling prices,dynamic revenue team,specialized QC,sturdy factories,superior quality services for China Forming Machine and Rolling Machine, With a state-of-the-art thorough marketing feedback system and 300 skilled workers’ hard work, our company has developed all kinds of solutions ranging from high class, medium class to low class. This whole selection of fine products offers our customers different choices. Besides, our company sticks to high quality and reasonable price, and we also give good OEM services to many famous brands.

MAIN TECHNICAL PARAMETERS

| PLC | Mitsubishi |

| Servo system | Yaskawa, Japan |

| Inverter | Delta (Taiwan, China) |

| Touch screen | Vinylon (Taiwan, China) |

| Low-voltage electrical appliances | Schneider (France) |

| DC speed regulation | Continental (USA) |

| Encoder | Omron (Japan) |

PRODUCTION PROCESS

Uncoiling → Leveling → cold roll forming → Hydraulic Follow → Up cutting → Discharging

MAIN COMPONENTS

The roll forming production line is mainly composed with the following:

Uncoiling machine, leveling machine, roll forming machine, cutting machine, hydraulic station and control station.

The hydraulic station provide the power for the cutting machine, the control station control the forming speed, the control station adopts PLC system with touch screen, the system is capable to read the CAD drawing directly, the operator could also input the product information through touch screen. The roll forming machine make the final product and the cutting machine make the final product to the specific length. The production line equip with individual frame, the frame is capable to adjust based on the size of the product automatically. The PLC system is capable to adjust the speed of the whole production line automatically

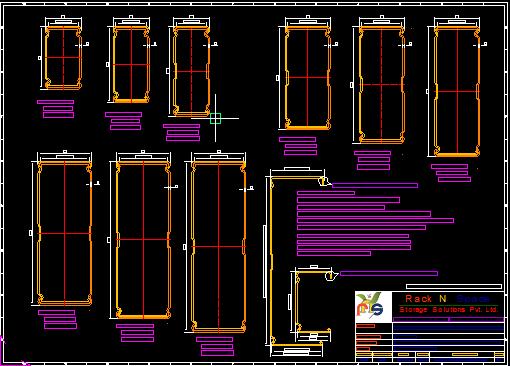

WORKPIECE SAMPLES

APPLICATION

This roll forming production line is used to produce the storage rack cross arms, the arms are widely used in storage warehouse, storage frames; the roll forming production line is capable to produce different size of the cross arms.

Storage shelf beam forming machine is a machine used to produce storage shelf beams. It is designed to take metal slats and form them into the desired shape and size of the storage rack transom.

Roll formers typically consist of a series of rollers and tools that gradually bend and shape metal strip into the desired profile. This machine can be adjusted according to specific requirements to produce storage rack beams of different sizes and shapes.