Manufacturer of China Gear Box Transmission System Motor Drives Warehouse Shelve Racks Roll Forming Machine

The really wealthy projects administration experiences and a person to just one assistance model make the higher importance of company communication and our easy understanding of your expectations for Manufacturer of China Gear Box Transmission System Motor Drives Warehouse Shelve Racks Roll Forming Machine, We often concertrating on creating new creative solution to meet request from our customers everywhere in the planet. Sign up for us and let’s make driving safer and funnier with each other!

The really wealthy projects administration experiences and a person to just one assistance model make the higher importance of company communication and our easy understanding of your expectations for China Roll Forming Machine, Shelve Racks, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad and create a great future together.

MAIN TECHNICAL PARAMETERS

| PLC | Mitsubishi |

| Servo system | Yaskawa, Japan |

| Inverter | Delta (Taiwan, China) |

| Touch screen | Vinylon (Taiwan, China) |

| Low-voltage electrical appliances | Schneider (France) |

| DC speed regulation | Continental (USA) |

| Encoder | Omron (Japan) |

PRODUCTION PROCESS

Uncoiling → Leveling → cold roll forming → Hydraulic Follow → Up cutting → Discharging

MAIN COMPONENTS

The roll forming production line is mainly composed with the following:

Uncoiling machine, leveling machine, roll forming machine, cutting machine, hydraulic station and control station.

The hydraulic station provide the power for the cutting machine, the control station control the forming speed, the control station adopts PLC system with touch screen, the system is capable to read the CAD drawing directly, the operator could also input the product information through touch screen. The roll forming machine make the final product and the cutting machine make the final product to the specific length. The production line equip with individual frame, the frame is capable to adjust based on the size of the product automatically. The PLC system is capable to adjust the speed of the whole production line automatically

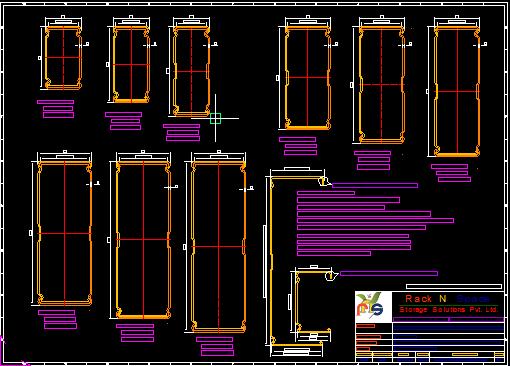

WORKPIECE SAMPLES

APPLICATION

This roll forming production line is used to produce the storage rack cross arms, the arms are widely used in storage warehouse, storage frames; the roll forming production line is capable to produce different size of the cross arms.

The really wealthy projects administration experiences and a person to just one assistance model make the higher importance of company communication and our easy understanding of your expectations for Manufacturer of China Gear Box Transmission System Motor Drives Warehouse Shelve Racks Roll Forming Machine, We often concertrating on creating new creative solution to meet request from our customers everywhere in the planet. Sign up for us and let’s make driving safer and funnier with each other!

Manufacturer of China Roll Forming Machine, Shelve Racks, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad and create a great future together.