Fast delivery Storage Rack Roll Forming Making Machinery Used Supermarket Shelf

With responsible good quality method, good status and excellent client services, the series of solutions produced by our company are exported to lots of countries and regions for Fast delivery Storage Rack Roll Forming Making Machinery Used Supermarket Shelf, We warmly welcome domestic and abroad buyers deliver inquiry to us ,we now have 24hours doing work team! Anytime anywhere we are still here to be your partner.

With responsible good quality method, good status and excellent client services, the series of solutions produced by our company are exported to lots of countries and regions for China Storage Rack Roll Forming Machine and Upright Roll Forming Machine, Our company adheres to the spirit of “lower costs, higher quality, and making more benefits for our clients”. Employing talents from the same line and adhering to the principle of “honesty, good faith, real thing and sincerity”, our company hopes to gain common development with clients from both at home and abroad!

MAIN TECHNICAL PARAMETERS

| Configurations | 3T Manual Uncoiler(2 SETS), Roll Forming, Electric-Motor, Mould Cutting, hydraulic station, Control Cabinet |

| Control System | Automatic Colored Touch ScreenDelta brand PLC Inverter |

| Main Power | 7.5 KW |

| Pump Power | 4 KW |

| Power Supply | 380V, 3-Phase, 50Hz |

| Forming Speed | 8-10 m/min |

| Roll Station | 17 roller station |

| Shaft Diameter | 57mm |

| Feeding Thickness | 1.8mm |

| Overall Size | About 7200×1200×1500mm |

| Total Weight | Approximately 3600KGS |

PRODUCTION PROCESS

Uncoiling → Leveling → Servo Feeding → Punching → Roll Forming → Cutting → Discharging

MAIN COMPONENTS

Uncoiler: automatically release the material coil according to the speed of the whole line

Servo Feeding Machine: Feed the sheet according to the actual step length required for punching

Punching press: Used to punching holes in the plate

Roll Forming Machine: Used to achieve the final required interface shape through the roll forming process of the required finished plate shape

Cutting Machine: It is to cut the formed work piece to length

Electrical Control Unit: The unit is equipped with PLC and tough screen, it control the whole production line.

Hydraulic Station: Provide power for punching machine and cutting machine

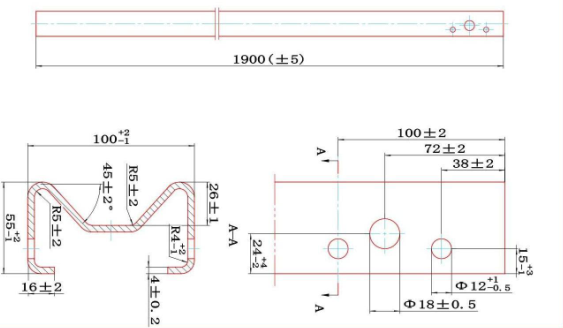

WORKPIECE SAMPLES

APPLICATION

The roll forming production line is used to produce storage racks for warehouse and storage frame.

Storage shelf forming machine is a kind of machinery used to manufacture storage shelves. It is a specialized machine designed to form sheet metal into specific profiles, which are then used to build storage shelves.

The roll forming process involves feeding a sheet metal into a machine where a series of rollers gradually shape the sheet metal into the desired profile. The machine usually consists of multiple stations, each with a set of rollers that perform a specific forming operation. These rolls can be adjusted to produce profiles of different sizes and shapes. Storage shelf forming machine is often used in logistics, warehousing, retail and other industries. Storage shelves are indispensable for organizing and storing goods. The machine efficiently and precisely produces storage racks with consistent quality and precision.

Some key features of a storage rack forming machine may include: Feed system:

The hydraulic or pneumatic system that feeds sheet metal into the machine.

Roll Forming Station: Multiple sets of rollers that gradually transform flat sheet metal into the desired storage rack rack profile.

Cutting system: The cutting mechanism that trims the final profile to the desired length.

Control Panel: Interface with machine control settings and operating parameters.

Safety function: safety protection cover, emergency stop button and other safety measures to protect operators during operation.

Depending on the specific requirements of the storage rack design, the machine may also include additional functions such as punching, embossing and bending functions.Overall, the storage shelf forming machine is essential