Fixed Competitive Price China Professional Processing Upe, Oily Nylon, PTFE and Other Chain Guides, Plastic Chain Support

Well-run gear, qualified revenue workforce, and superior after-sales companies; We’ve been also a unified huge loved ones, anyone persist with the organization benefit “unification, determination, tolerance” for Fixed Competitive Price China Professional Processing Upe, Oily Nylon, PTFE and Other Chain Guides, Plastic Chain Support, The continual availability of high grade products in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market.

Well-run gear, qualified revenue workforce, and superior after-sales companies; We’ve been also a unified huge loved ones, anyone persist with the organization benefit “unification, determination, tolerance” for China Conveyor Belt Wear Strips, Guiding, We can give our clients absolute advantages in product quality and cost control, and now we have full range of molds from up to one hundred of factories. As product updating fast, we succeed in developing many high quality solutions for our clients and get high reputation.

APPLICATION

Truck carriage wall plate roll forming machine is mainly used to produce the parts on the truck, including the bottom plate, the top plate and the column on the truck. It can be applied to refrigerated trucks, large trucks, trucks, etc.

MAIN TECHNICAL PARAMETERS

| Material quality | hot-rolled steel plate |

| Yield strength of raw material | 235Mpa |

| Tensile strength of raw material: | 450Mpa |

| Coil outer diameter: | ≤Ф1300 mm |

| Inner diameter of coil | Ф508 |

| Strip width | ≤1000mm |

| Strip thickness | 1~1.2mm |

| Single roll weight | ≤7000 kg |

PRODUCTION PROCESS

Uncoiling → Leveling → Looper (Storage) → Servo Feeding, Pre-Cutting → Looper (Storage) → Cold Forming → Point Welding → Cutting → Discharging

MAIN COMPONENTS

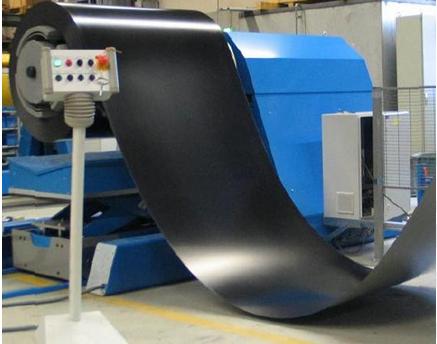

1. Uncoiler(1 set):

The automatic uncoiler of the uncoiler, when the roll is installed on the uncoiler shaft, the uncoiler shaft actively rotates during the actual operation of the entire line and its traction power comes from the uncoiler motor. The uncoiler can automatically release the material coil according to the running speed of the whole line.

2. Electric control unit

The whole line adopts the man-machine control mode combining PLC and touch screen. The specification parameters, quantity and system parameters of the parts can be set through the touch screen. Multiple sets of operating instructions can be stored at one time. The degree of automation is high. It has an alarm function in the event of an abnormality in the production line. The operation of the entire production line can be monitored through the control system. After power failure or abnormal shutdown, processing can be continued according to the previously set working parameters.

| Name | Brand |

| PLC | Mitsu |

| Frequency converter | Delta |

| Touch screen | Vinylon |

| Low-voltage electrical appliances | Schneider |

| Servo controller | Yaskawa |

3. Storage (silo) device

The storage device consists of two parts: the arc-shaped roller and the supporting device. There are four groups of arc-shaped rollers, which are placed on both sides of the two storage bins. They are composed of an arc frame and a set of flexible rollers. The surface of the roller is plated with hard chrome. A photoelectric switch is installed in the pit of the discharge bin to control the entry.The position of the material roll in the pit, so that the speed of each working part is perfectly matched.

Well-run gear, qualified revenue workforce, and superior after-sales companies; We’ve been also a unified huge loved ones, anyone persist with the organization benefit “unification, determination, tolerance” for Fixed Competitive Price China Professional Processing Upe, Oily Nylon, PTFE and Other Chain Guides, Plastic Chain Support, The continual availability of high grade products in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market.

Fixed Competitive Price China Conveyor Belt Wear Strips, Guiding, We can give our clients absolute advantages in product quality and cost control, and now we have full range of molds from up to one hundred of factories. As product updating fast, we succeed in developing many high quality solutions for our clients and get high reputation.