Newly Arrival China Factory Making Wholesale Prices Metal Storage Rack Shelf Frame Profiles Cold Rollling Roll Forming Machine

Along with the “Client-Oriented” business philosophy, a rigorous good quality management method, state-of-the-art producing devices as well as a potent R&D workforce, we always supply high quality products and solutions, outstanding products and services and aggressive costs for Newly Arrival China Factory Making Wholesale Prices Metal Storage Rack Shelf Frame Profiles Cold Rollling Roll Forming Machine, We believe you will be satisfied with our reasonable price, high quality products and fast delivery. We sincerely hope you can give us an opportunity to serve you and be your best partner!

Along with the “Client-Oriented” business philosophy, a rigorous good quality management method, state-of-the-art producing devices as well as a potent R&D workforce, we always supply high quality products and solutions, outstanding products and services and aggressive costs for China Roll Forming Machine and Cold Roll Forming Machine, We’ve got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

MAIN TECHNICAL PARAMETERS

| PLC | Mitsubishi |

| Servo system | Yaskawa, Japan |

| Inverter | Delta (Taiwan, China) |

| Touch screen | Vinylon (Taiwan, China) |

| Low-voltage electrical appliances | Schneider (France) |

| DC speed regulation | Continental (USA) |

| Encoder | Omron (Japan) |

PRODUCTION PROCESS

Uncoiling → Leveling → cold roll forming → Hydraulic Follow → Up cutting → Discharging

MAIN COMPONENTS

The roll forming production line is mainly composed with the following:

Uncoiling machine, leveling machine, roll forming machine, cutting machine, hydraulic station and control station.

The hydraulic station provide the power for the cutting machine, the control station control the forming speed, the control station adopts PLC system with touch screen, the system is capable to read the CAD drawing directly, the operator could also input the product information through touch screen. The roll forming machine make the final product and the cutting machine make the final product to the specific length. The production line equip with individual frame, the frame is capable to adjust based on the size of the product automatically. The PLC system is capable to adjust the speed of the whole production line automatically

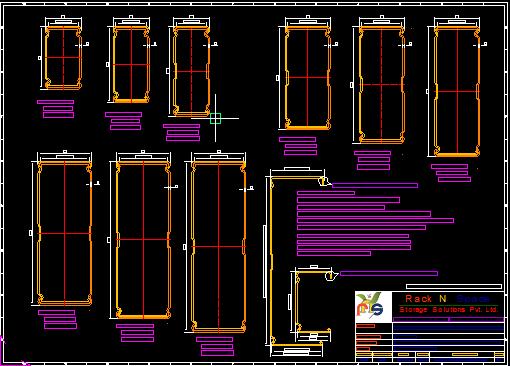

WORKPIECE SAMPLES

APPLICATION

This roll forming production line is used to produce the storage rack cross arms, the arms are widely used in storage warehouse, storage frames; the roll forming production line is capable to produce different size of the cross arms.

Along with the “Client-Oriented” business philosophy, a rigorous good quality management method, state-of-the-art producing devices as well as a potent R&D workforce, we always supply high quality products and solutions, outstanding products and services and aggressive costs for Newly Arrival China Factory Making Wholesale Prices Metal Storage Rack Shelf Frame Profiles Cold Rollling Roll Forming Machine, We believe you will be satisfied with our reasonable price, high quality products and fast delivery. We sincerely hope you can give us an opportunity to serve you and be your best partner!

Newly Arrival China Roll Forming Machine and Cold Roll Forming Machine, We’ve got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.