ODM Supplier China Full Automatic Stainless Steel Storage Rack Roll Forming

Our commission should be to serve our end users and purchasers with finest top quality and competitive portable digital products and solutions for ODM Supplier China Full Automatic Stainless Steel Storage Rack Roll Forming, We’re keeping chasing WIN-WIN situation with our consumers. We warmly welcome clientele from all around the environment coming above for a visit and establishing long lasting connection.

Our commission should be to serve our end users and purchasers with finest top quality and competitive portable digital products and solutions for China Cold Roll Forming Machine, Roll Forming Machine, Custom orders are acceptable with different quality grade and customer’s especial design. We are looking forward to establish the good and successful cooperation in business with long terms from the customers of all over the world.

MAIN TECHNICAL PARAMETERS

| Configurations | 3T Manual Uncoiler(2 SETS), Roll Forming, Electric-Motor, Mould Cutting, hydraulic station, Control Cabinet |

| Control System | Automatic Colored Touch ScreenDelta brand PLC Inverter |

| Main Power | 7.5 KW |

| Pump Power | 4 KW |

| Power Supply | 380V, 3-Phase, 50Hz |

| Forming Speed | 8-10 m/min |

| Roll Station | 17 roller station |

| Shaft Diameter | 57mm |

| Feeding Thickness | 1.8mm |

| Overall Size | About 7200×1200×1500mm |

| Total Weight | Approximately 3600KGS |

PRODUCTION PROCESS

Uncoiling → Leveling → Servo Feeding → Punching → Roll Forming → Cutting → Discharging

MAIN COMPONENTS

Uncoiler: automatically release the material coil according to the speed of the whole line

Servo Feeding Machine: Feed the sheet according to the actual step length required for punching

Punching press: Used to punching holes in the plate

Roll Forming Machine: Used to achieve the final required interface shape through the roll forming process of the required finished plate shape

Cutting Machine: It is to cut the formed work piece to length

Electrical Control Unit: The unit is equipped with PLC and tough screen, it control the whole production line.

Hydraulic Station: Provide power for punching machine and cutting machine

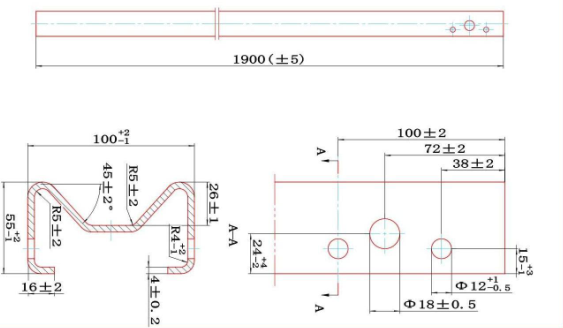

WORKPIECE SAMPLES

APPLICATION

The roll forming production line is used to produce storage racks for warehouse and storage frame.

Our commission should be to serve our end users and purchasers with finest top quality and competitive portable digital products and solutions for ODM Supplier China Full Automatic Stainless Steel Storage Rack Roll Forming, We’re keeping chasing WIN-WIN situation with our consumers. We warmly welcome clientele from all around the environment coming above for a visit and establishing long lasting connection.

ODM Supplier China Cold Roll Forming Machine, Roll Forming Machine, Custom orders are acceptable with different quality grade and customer’s especial design. We are looking forward to establish the good and successful cooperation in business with long terms from the customers of all over the world.