OEM Manufacturer Ztrfm Automatic Pallet Shelving Rack Upright Support Roll Forming Storage Shelf Beam Machine Factory

We strive for excellence, service the customers”, hopes to become the best cooperation team and dominator enterprise for personnel, suppliers and customers, realizes value share and continuous promotion for OEM Manufacturer Ztrfm Automatic Pallet Shelving Rack Upright Support Roll Forming Storage Shelf Beam Machine Factory, Our assistance concept is honesty, aggressive, realistic and innovation. With all your guidance, we’re going to develop much far better.

We strive for excellence, service the customers”, hopes to become the best cooperation team and dominator enterprise for personnel, suppliers and customers, realizes value share and continuous promotion for China Machine and Storage Rack, Our company has abundant strength and possesses a steady and perfect sales network system. We wish we could establish sound business relationships with all customers from at home and abroad on the basis of mutual benefits.

MAIN TECHNICAL PARAMETERS

| PLC | Mitsubishi |

| Servo system | Yaskawa, Japan |

| Inverter | Delta (Taiwan, China) |

| Touch screen | Vinylon (Taiwan, China) |

| Low-voltage electrical appliances | Schneider (France) |

| DC speed regulation | Continental (USA) |

| Encoder | Omron (Japan) |

PRODUCTION PROCESS

Uncoiling → Leveling → cold roll forming → Hydraulic Follow → Up cutting → Discharging

MAIN COMPONENTS

The roll forming production line is mainly composed with the following:

Uncoiling machine, leveling machine, roll forming machine, cutting machine, hydraulic station and control station.

The hydraulic station provide the power for the cutting machine, the control station control the forming speed, the control station adopts PLC system with touch screen, the system is capable to read the CAD drawing directly, the operator could also input the product information through touch screen. The roll forming machine make the final product and the cutting machine make the final product to the specific length. The production line equip with individual frame, the frame is capable to adjust based on the size of the product automatically. The PLC system is capable to adjust the speed of the whole production line automatically

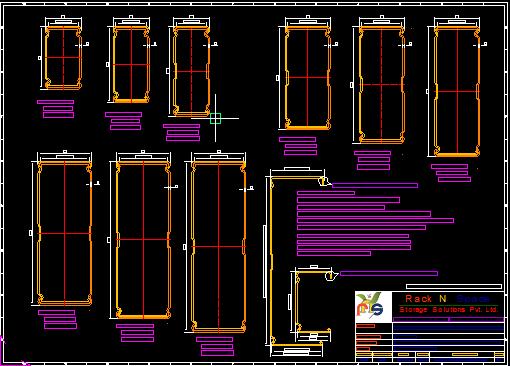

WORKPIECE SAMPLES

APPLICATION

This roll forming production line is used to produce the storage rack cross arms, the arms are widely used in storage warehouse, storage frames; the roll forming production line is capable to produce different size of the cross arms.

Metal Shelf Storage Rack Beam Upright Roll Forming Making Machinery details:

Feeding material: aluzinc/galvanized steel or as customer request

Feeding Thickness : 0.4-0.6mm

Rolling stages:18stages

Productivity: 8m/min

Main motor power:5.5kw

Side plate thickness:25mm

Roller material: GCr15 steel

Control systerm: PLC control system with touch screen

Roller driven type:Chain and gear transmission

Power supply:380v,3phase,50hz