OEM/ODM Factory China Machinery Galvanized Metal Glazed Tile/Sheet Metal Roof Roll Forming Machine Price

We now have a skilled, performance team to supply good quality services for our consumer. We often follow the tenet of customer-oriented, details-focused for OEM/ODM Factory China Machinery Galvanized Metal Glazed Tile/Sheet Metal Roof Roll Forming Machine Price, Welcome any inquiry to our corporation. We are going to be glad to establish pleasant company associations along with you!

We now have a skilled, performance team to supply good quality services for our consumer. We often follow the tenet of customer-oriented, details-focused for China Galvanized Metal Glazed Tile Machine and Sheet Metal Roof Machine, Establish long term and win-win business relationships with all our customers, share the success and enjoy the happiness of spreading our products to the world together. Trust us and you will gain more. Be sure to feel free to contact us for more information, we assure you of our best attention at all times.

PRODUCT DESCRIPTION

This glazed tile roll forming machine is used for making the glazed tile,which is widely used in factories, houses, hotels, villas and other industrial and civil buildings.

MAIN PARAMETERS

Material: Galvanized sheet

Yield strength of raw materials: ≤235Mpa

Tensile strength of raw materials: ≤550Mpa

Outer Diameters of Coils: ≤Ф1300 mm

Inner Diameter of Coils: Ф508

Steel strap width: ≤1000mm

Steel Strap Thickness: 0.2~0.4mm

Weight/Coil: ≤5000 kg

PRODUCTION PROCESS

The glazed tiles manufacturing machine products are carried out according to the following process:

Uncoiling → Looper (Storage) → Cold Forming → Pressing Table & Cutting → Discharging

MAIN COMPONENTS&SPECIFICATION

| No | Items Name | Specifications |

| 1 | Decoiler | Manual Type; Coils ID: Ф508mm; Coil OD: Ф1300mm; Coil Width: 1000mm; Coil weight: ≤5000 kg |

| 2 | Roll Forming Machine | The forming unit is driven by motor, reducer and sub-reducer. Molding machine memorial arch for independent memorial arch structure (non – plate structure), stable performance, reliable, high precision. The base is welded steel structure. Annealing after welding.The molding roller is designed by professional software, and the material is made of high quality 45 steel and hard chrome plating. Forming passes: 16 passes (subject to the final design); Shaft diameter: φ70mm (subject to final design); Motor power: 5.5kw Maximum linear speed: 2~5 m/min |

| 3 | Hydraulic Cutting | Cutter mode adopts no scrap cutting. Cutter material: Cr12MoV (hardness is HRC58~62 after quenching); Measuring accuracy: ±1.5mm |

| 7 | Electrical Control Cabinet | PLC: Mitsubishi; Inverter: Delta; Touch screen: Vinylon (Taiwan, China); Low-voltage electrical appliances: Schneider (France); Encoder: Omron (Japan) |

| 8 | Hydraulic System | Hydraulic system USES filter, the cleanliness of oil to ensure 6-8 grade |

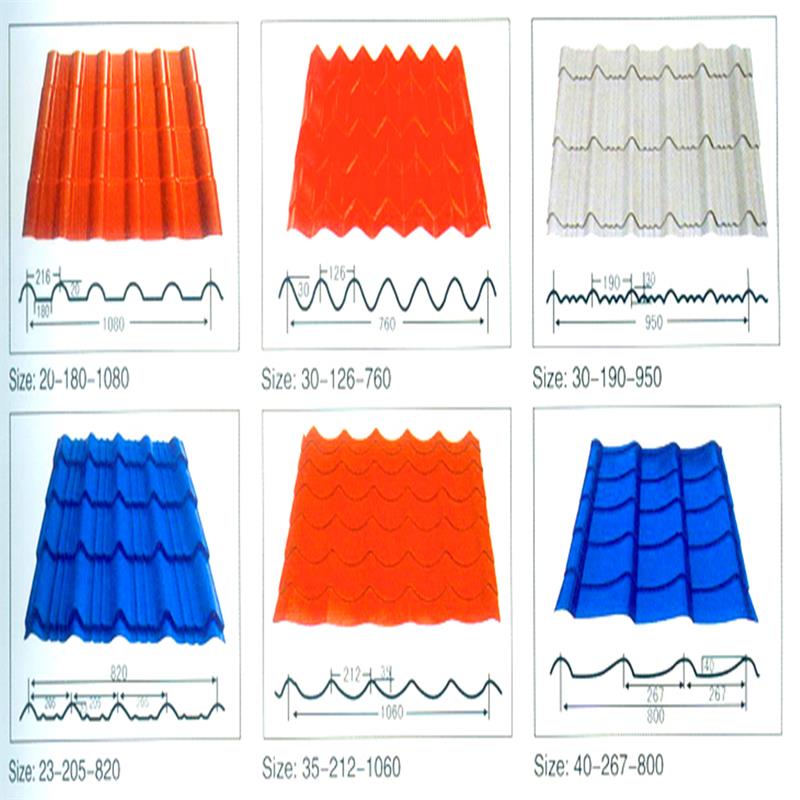

WORKPIECE SAMPLES

Glazed tile roll forming machine;glazed tiles manufacturing machine;glazed tile forming machine

Glazed tile roll forming machines are innovative and high-tech equipment specifically designed for producing glazed tiles, which are widely used in the construction industry for roofing and exterior cladding applications. These machines are capable of rolling metal sheets of different thicknesses and widths into glazed tiles of varying sizes and shapes, such as corrugated sheets, trapezoidal sheets, and so on.

The glazed tile roll forming machines are equipped with advanced features, like automatic rewinding systems, hydraulic press systems, cutting tools, and more, which greatly enhance their efficiency and productivity. They offer high precision and accuracy, ensuring that the glazed tiles produced are of excellent quality. These machines also come with user-friendly interfaces and are easy to operate, making them ideal for both small-scale and large-scale production.

Using glazed tile roll forming machines provides numerous benefits for individuals and businesses engaged in the construction industry. For one, it reduces material waste and saves time and money in production costs. Moreover, the glazed tiles produced are durable and weather-resistant, making them ideal for use in different climatic conditions. They are also available in different colors and designs, providing endless possibilities for homeowners and builders to create customized and appealing roofing and cladding solutions.

In conclusion, the glazed tile roll forming machines are an excellent investment for those looking to grow their construction business. With their advanced features, efficiency, and durability, they offer a reliable and cost-effective solution for producing top-quality glazed tiles. As the construction industry continues to grow and evolve, these machines are becoming increasingly popular and are sure to remain an integral part of the sector’s future.