Professional China Semi Automatic CZ Purlin Roll Forming Machine

To become the stage of realizing dreams of our employees! To build a happier, a lot more united and more expert workforce! To reach a mutual profit of our buyers, suppliers, the society and ourselves for Professional China Semi Automatic CZ Purlin Roll Forming Machine, We are going to provide most effective quality, quite possibly the most current market aggressive rate, for each and every new and outdated consumers with the most great environmentally friendly solutions.

To become the stage of realizing dreams of our employees! To build a happier, a lot more united and more expert workforce! To reach a mutual profit of our buyers, suppliers, the society and ourselves for China Purlin Machine and Purlin Rolling Machine, Corporate goal: Customers’ satisfaction is our goal, and sincerely hope to establish long-terms stable cooperative relations with customers to jointly develop the market. Building brilliant tomorrow together!Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

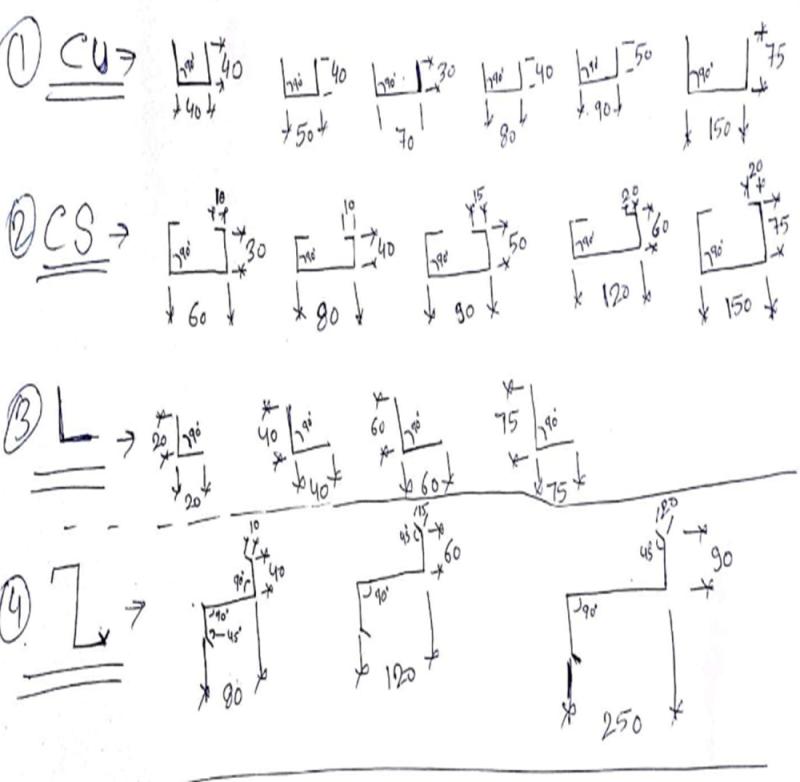

MAIN TECHNICAL PARAMETERS

|

Profile |

Web |

Flange |

Lip |

Thickness |

|

C |

80-300mm |

40-80mm |

10-25mm |

1.2-3.2mm |

|

Z |

120-300mm |

40-80mm |

10-25mm |

1.2-3.2mm |

Fast Changing Structure

PRODUCTION PROCESS

Uncoiling → Leveling → Looper (Material Storage) → Servo Feeding → Multi-Station Punching Machine (Cutting Off) → Roll Forming Machine → Finished Products

MAIN COMPONENTS

This production line is mainly composed by following parts:

| No | Items Name | Specifications |

| 1 | Decoiler | Single head mode, single support; Coils ID: Ф508mm; Coil OD : Ф1200mm; Coil Width : 500mm; Coil weight: ≤5000 kg; |

| 2 | Leveling Machine | 5 roller leveling; Max. speed: 20m/min; Max. Leveling width: 500mm; Max. Coil thickness: 1~3mm; Power of leveling machine: approx. 7.5kw (subject to final design) |

| 3 | Servo Feeder | Maximum feeding speed: 30m/min; Maximum feed width: ≤500mm; Allowed feed thickness: ≤3mm; Precision of feeding: ±0.2mm/step; Servo motor: Japan, Yaskawa; Servo Motor Power: aprox.4.4KW (according to final design) |

| 4 | Multi-Punching | To complete the punching holes on the profile. |

| 5 | Quick Change Roll Forming Machine | There are two types of nuts on the outside of the archway: left-handed (lower shaft) and right-handed (upper shaft). Archway material: QT450. 8/13Quotation documents; Roller shaft material: 40Cr, quenched and tempered, hardness is HRC45~50; Parameters: Forming passes: 36 passes (subject to the final design); Archway sorties: 36+32=68 sorties; Shaft diameter of forming machine: φ70mm (subject to final design); Motor power: 55kw; Maximum linear speed: 2~8m/min |

| 6 | Hydraulic Cutting | The cutter mode adopts blanking shearing; Blade materialBlade material: Cr12MoV (hardness after quenching HRC58~62); Parameter: cutting accuracy: ±1.5mmAccuracy: ±1.5mm |

| 7 | Electrical Control Cabinet | PLC: Mitsubishi; Inverter: Delta; Touch screen: Vinylon (Taiwan, China); Low-voltage electrical appliances: Schneider (France); Encoder: Omron (Japan); Servo controller: Yaskawa (Japan) |

| 8 | Hydraulic System | Hydraulic system USES filter, the cleanliness of oil to ensure 6-8 grade |

WORKPIECE SAMPLES OF TILE MAKING MACHINE

CZ quick change roll forming machine line; CZUL fast change roll forming machine; c purlin fast change roll forming machine; CZ Purlin Roll Forming Machine

C Z U L fast change roll forming machines are high quality industrial equipment designed to provide efficient and accurate roll forming solutions for various applications. These machines are capable of producing high volumes of precision roll formed products with incredible speed and accuracy.

The C Z U L fast change roll forming machines are engineered to handle a broad range of materials and thicknesses. They feature advanced technology and automated systems that ensure uniformity, consistency, and precision in the finished products. The machines can also be customized to meet specific production needs, making them versatile and adaptable to different manufacturing environments.

With their fast change capabilities, the C Z U L roll forming machines can switch between different roll sets quickly, reducing downtime and increasing productivity. They are easy to operate, requiring minimal human intervention, and are designed to enhance safety and reduce waste.

In summary, the C Z U L fast change roll forming machines are cutting-edge equipment that offers a range of benefits, including speed, precision, efficiency, safety, and versatility. They are engineered to meet the needs of modern manufacturing and provide sustainable solutions for the production of high-quality roll formed products.