Products

-

Raintech Multi-Specification Storage Shelf Making Machine Supermarket Shelf Roll Forming Machine

Storage rack is widely applied in storage and logistic industry. Our roll forming machine can continuously and automatically produce the racks. Meanwhile, the industry is developing, more and more customized parts from storage and logistic industry can be produced from roll forming machines.

Product Parameters:Technical Parameter

Configurations 3T Manual Uncoiler(2 SETS), Roll Forming, Electric-Motor, Mould Cutting, hydraulic station, Control Cabinet Control System Automatic Colored Touch Screen

Delta brand PLC InverterMain Power 7.5 KW Pump Power 4 KW Power Supply 380V, 3-Phase, 50Hz Forming Speed 8-10 m/min Roll Station 17 roller station Shaft Diameter 57mm Feeding Thickness 1.8mm Overall Size About 7200×1200×1500mm Total Weight Approximately 3600KGS Manufacturing Processes Transmission mode: Main motor → Gear reducer → Drive bevel gear box → Clutch → Lower roller shaft of the archway.Workpiece Picture

Transmission mode: Main motor → Gear reducer → Drive bevel gear box → Clutch → Lower roller shaft of the archway.Workpiece Picture

-

Raintech Good Quality Slitting Machine Line Coil Slitting Line Machine

Product Description

The slitting line is also called slitting unit, slitting machine, slitting machine, and scissors. It cuts the metal coils into strips of various required widths, and then collects the strips into small rolls for the next process. It is a necessary equipment for precision cutting of transformers, motor industries and other metal strips.

Product Parameters

Model/ Items Thickness (mm) Width (mm) Slitting Number Slitting Speed m/min Coil Weight (ton) RSL-0.5×1000 0.15-0.5 300-1000 12 50-150 7 RSL-0.5×1300 0.15-0.5 500-1300 24 50-150 7 RSL-2X650 0.3-2 200-650 10-30 50-150 7 RSL-2X1000 0.3-2 300-1000 10-30 50-150 7/15 RSL-2×1300 0.3-2 500-1300 12-30 50-180 7/15 RSL-2×1600 0.3-2 500-1600 12-30 50-180 7/15 RSL-3×1600 0.3-3 500-1600 8-30 50-180 15 RSL-3×1800 0.3-3 900-1800 8-30 50-180 20 RSL-4×1600 1-4 900-1600 6-30 50-120 20 RSL-6×1600 1-6 900-1600 6-30 30-80 30 RSL-10×2000 2-10 900-2000 5-30 30-50 30 RSL-12×2000 3-12 900-2000 5-30 20-40 30 RSL-16×2000 3-16 900-2000 5-30 20-40 40 -

Raintech 220mm-300mm Thickness Solar PV Bracket Roll Forming Machine

The production process:

uncoiling-leveling-servo feeding-multi-station punching-looper(storage)-roll forming -shear discharge

Technical ParameterConfigurations Manual Uncoiler, Roll Forming, Electric-Motor, Mould Cutting, hydraulic station, Control Cabinet Control System Automatic Colored Touch Screen

Delta brand PLC InverterMaximum allowable feeding width ≤300 Allowable feeding thickness ≤2mm Single feeding error ≤±0.2mm (this tolerance does not add up) Servo motor brand YASKAWA, Japan Servo motor power 9Cr2Mo(or GCr15), hardness HRC55-60 Molding passes 15 passes (subject to final design) Axle diameter of molding machine φ60mm (subject to final design) Motor power 22KW Siemens Bede frequency conversion motor Maximum linear speed 2~14m/min Workpiece Picture And Section

-

High Quality Steel Metal Sheet Side Wall Panel Cold Roll Forming Machine

Product Description

Material quality steel plate, aluminum plate Yield strength of raw materials ≤350Mpa Tensile strength of raw materials ≤550Mpa Coiling material outside diameter: ≤Ф1300 mm Inner diameter of coil Ф508 Width of steel belt: ≤600mm Thickness of steel belt 0.6~1.2mm Single roll weight ≤5000 kg Production Technology Process:

The products of the production line are carried out according to the Technological Process:

Uncoiling → Looper (material storage)→ quick change type cold bending molding → cut off → discharge.

Parameters: Forming times: 28 (subject to the final design)

Shaft diameter of molding machine: φ70

Motor power: about 45KW

Maximum linear speed: 5~15m/min -

High Precision Automatic Stainless Steel Slitting Line

The slitting line is also called slitting unit, slitting machine, slitting machine, and scissors. It cuts the metal coils into strips of various required widths, and then collects the strips into small rolls for the next process. It is a necessary equipment for precision cutting of transformers, motor industries and other metal strips.

Detailed Photos

It is composed of the following:

1. entry coil car,

2. uncoiler,

3. slitter,

4. scrap coiler,

5. tension unit,

6. recoiler, etc.Our slitting machine carries out slitting on cold or hot rolling carbon steel, tinplates, stainless steel, and other kinds of metal that have coated surfaces. It is a useful slitting machine, widely used during the processing of home appliances, automobiles, hardware, steel products and more

-

High Quality Carbon Steel Coil Processing Cut to Length Line

Brief Introduction of carbon steel coil processing line:

A cut to length line is generally used for jobs like uncoiling, straightening, measuring, cross-cutting to length and stacking of various materials such as cold or hot rolling carbon steel, tinplate, stainless steel, and other kinds of metal with coated surfaces.

Features of High Speed Cut to Length Line :

Features of High Speed Cut to Length Line :

1. high speed cut to length line , speed can be 80m/min.

2. High leveling precision

3. It has a hard chrome plated surface and is durable and abrasion resistant.

4. It is used together with a hydraulic shear or an air-clutch shear to carry out fast shearing and convenient clearance adjustment.

5. raw material : CR HR, PPGI , SSProduct Parameters

Model Coil thickness(mm) Coil width(mm) cut tolerance(mm) Line speed(max)(m/min) Shear number(max)(spm) Coil weight(ton) RCL-2X1300 0.2-2 300-1300 +/- 0.3 60 50 7/15 RCL-2X1600 0.2-2 400-1600 +/- 0.3 60 50 7/15 RCL-2X1850 0.2-2 900-1850 +/- 0.3 50 40 20 RCL-3X1600 0.5-3 400-1600 +/- 0.3 50 40 15 RCL-3X1850 0.5-3 900-1850 +/- 0.3 50 40 20 RCL-3X2000 0.5-3 900-2000 +/- 0.3 45 40 30 RCL-6X1600 1-6 600-1600 +/- 1 25 20 20 RCL-6X2000 1-6 900-2000 +/- 1 25 20 30 RCL-8X2000 2-8 900-2000 +/- 1 20 20 30 RCL-12X2000 3-12 900-2000 +/- 1.5 20 10 30 RCL-16X2000 4-16 900-2000 +/- 2 15 8 30 -

Raintech Automatic Steel Coil Cut to Length Machine for Aluminium, Copper, Stainless Steel

Brief Introduction of carbon steel coil processing line:

A cut to length line is generally used for jobs like uncoiling, straightening, measuring, cross-cutting to length and stacking of various materials such as cold or hot rolling carbon steel, tinplate, stainless steel, and other kinds of metal with coated surfaces.

Product Parameters:

Model Coil thickness(mm) Coil width(mm) cut tolerance(mm) Line speed(max)(m/min) Shear number(max)(spm) Coil weight(ton) RCL-2X1300 0.2-2 300-1300 +/- 0.3 60 50 7/15 RCL-2X1600 0.2-2 400-1600 +/- 0.3 60 50 7/15 RCL-2X1850 0.2-2 900-1850 +/- 0.3 50 40 20 RCL-3X1600 0.5-3 400-1600 +/- 0.3 50 40 15 RCL-3X1850 0.5-3 900-1850 +/- 0.3 50 40 20 RCL-3X2000 0.5-3 900-2000 +/- 0.3 45 40 30 RCL-6X1600 1-6 600-1600 +/- 1 25 20 20 RCL-6X2000 1-6 900-2000 +/- 1 25 20 30 RCL-8X2000 2-8 900-2000 +/- 1 20 20 30 RCL-12X2000 3-12 900-2000 +/- 1.5 20 10 30 RCL-16X2000 4-16 900-2000 +/- 2 15 8 30 -

Raintech Truck Bodywork Panel Container Plate Cold Roll Forming Machine

Production process flow

Uncoiling (including automatic feeding trolley) → leveling and guiding → roll forming (including straightening) → cutting.1. Uncoiling:

The machine is in single-head mode, single support and manual tightening.

2. Servo Leveling Feeder:

The machine adopts 5 rollers for leveling and feeding (2 rollers on the upper layer, 3 rollers on the lower layer, screw adjustment), 1 pair of guide rollers, the feeding rollers are pneumatically clamped, and the servo motor provides power for it.

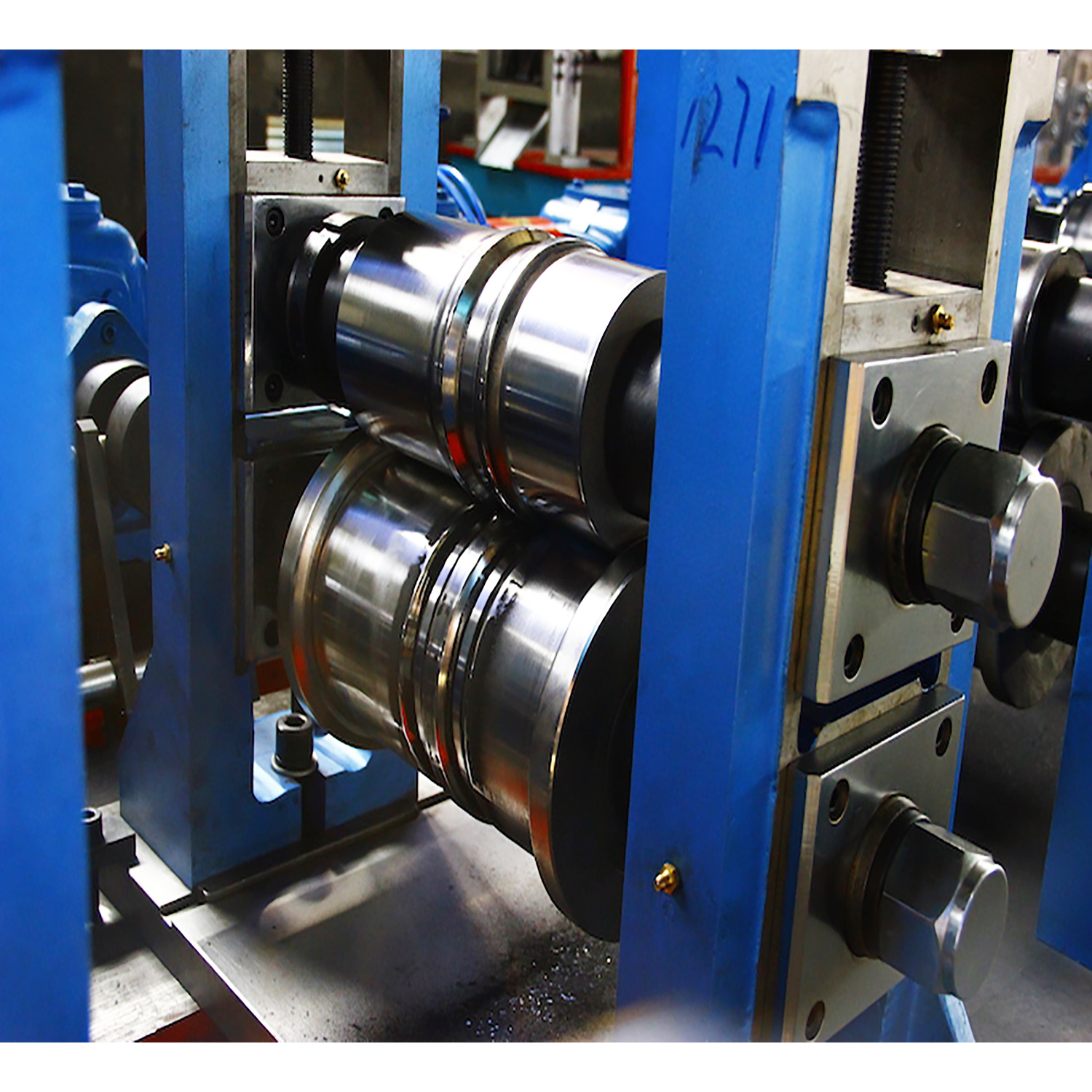

3. Roll Forming Machine

Used to achieve the final required shape through the roll forming process of the required finished plate. The material is made of high-quality mold steel Cr12, and the hardness after quenching reaches HRC58~62 (physical characteristics are equivalent to American material D2), which improves mechanical performance and life. The surface of the roller is polished after finishing. The roller has high precision and long life.

4. Cutting

Structure: power saw head, servo tracking system, base, special fixture -

2023 High Quality 1100 Glazed Roof Tile Roll Forming Machine

This glazed tile roll forming machine is used for making the glazed tile,which is widely used in factories, houses, hotels, villas and other industrial and civil buildings.

-

High Quality RSL 4X1500 Slitting Production Line

The slitting line is also called slitting unit, slitting machine, strip cutting machine, and scissors. It is mainly used for slitting and cutting coil materials such as tinplate, galvanized iron, silicon steel sheet, cold-rolled strip steel, stainless steel strip, aluminum strip, and steel strip. It cuts metal coils into strips of various widths, and then harvests the strips into small rolls for the next process. It is a necessary equipment for precision cutting of transformers, motor industries and other metal strips.

-

PHD2016 CNC High Speed Planar Drilling Milling Machine

The PHD2016 is a gantry moving CNC high-speed drilling and milling machine, mainly used for drilling, shaving, chamfering, grooves inside holes and milling of flanges, heat exchangers, tubeplates, rotary supports and other workpieces. It can be used for internal cold high-speed drilling with hard alloy drill bit or external cold drilling with high speed steel twist drill bit. Drilling depth of 10D (10x diameter) can be achieved with special crown drill bit. The machining process is NC and easy to operate. It can realize automatic, high precision and many kinds of mass production.

-

CNC High Speed Planar Gantry Moveable Drilling Milling Machine

The PHD2516 is a gantry moving CNC high-speed drilling and milling machine, mainly used for drilling, shaving, chamfering, grooves inside holes and milling of flanges, heat exchangers, tubeplates, rotary supports and other workpieces. It can be used for internal cold high-speed drilling with hard alloy drill bit or external cold drilling with high speed steel twist drill bit. Drilling depth of 10D (10x diameter) can be achieved with special crown drill bit. The machining process is NC and easy to operate. It can realize automatic, high precision and many kinds of mass production.