Wholesale OEM Industrial Large Metal Box Beam Step Beam Storage Cabinet Shelf Step Beam Production Line Roll Forming Machine

Sticking towards the theory of “Super Good quality, Satisfactory service” ,We are striving to become a superb business enterprise partner of you for Wholesale OEM Industrial Large Metal Box Beam Step Beam Storage Cabinet Shelf Step Beam Production Line Roll Forming Machine, We sincerely welcome domestic and foreign retailers who phone calls, letters asking, or to plants to barter, we’ll supply you excellent products and solutions plus the most enthusiastic provider,We look ahead on your check out as well as your cooperation.

Sticking towards the theory of “Super Good quality, Satisfactory service” ,We are striving to become a superb business enterprise partner of you for storage shelf beam roll forming machine, Our domestic website’s generated over 50, 000 purchasing orders every year and quite successful for internet shopping in Japan. We would be happy to have an opportunity to do business with your company. Looking forward to receiving your message !

MAIN TECHNICAL PARAMETERS

| PLC | Mitsubishi |

| Servo system | Yaskawa, Japan |

| Inverter | Delta (Taiwan, China) |

| Touch screen | Vinylon (Taiwan, China) |

| Low-voltage electrical appliances | Schneider (France) |

| DC speed regulation | Continental (USA) |

| Encoder | Omron (Japan) |

PRODUCTION PROCESS

Uncoiling → Leveling → cold roll forming → Hydraulic Follow → Up cutting → Discharging

MAIN COMPONENTS

The roll forming production line is mainly composed with the following:

Uncoiling machine, leveling machine, roll forming machine, cutting machine, hydraulic station and control station.

The hydraulic station provide the power for the cutting machine, the control station control the forming speed, the control station adopts PLC system with touch screen, the system is capable to read the CAD drawing directly, the operator could also input the product information through touch screen. The roll forming machine make the final product and the cutting machine make the final product to the specific length. The production line equip with individual frame, the frame is capable to adjust based on the size of the product automatically. The PLC system is capable to adjust the speed of the whole production line automatically

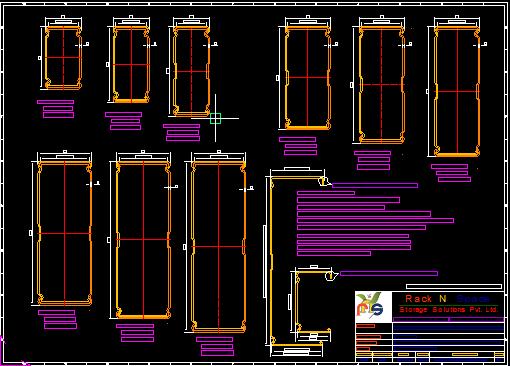

WORKPIECE SAMPLES

APPLICATION

This roll forming production line is used to produce the storage rack cross arms, the arms are widely used in storage warehouse, storage frames; the roll forming production line is capable to produce different size of the cross arms.

The storage shelf beam forming machine is a special equipment for manufacturing storage shelf beams through the roll forming process.

Roll forming is a continuous and efficient metal forming process in which a metal coil is passed through a series of rollers that gradually shape the metal into the desired profile. Warehouse rack beam roll forming machines typically consist of a series of rolling stations, each with its own set of rollers that progressively bend and shape the metal coil. Adjust the rollers to match the desired shape and size of the storage rack beams. The machine also includes an uncoiler to secure the metal coil and feed it into the roll forming process, and a cutting mechanism to shear the forming beam to the required length.

These machines are designed to produce warehouse racking beams with high precision and consistency. They are widely used in manufacturing, producing racking systems used in warehouses, distribution centers and other storage facilities. When considering a warehouse rack beam roll forming machine, it is important to evaluate factors such as required production capacity, material thickness and width specifications, and customization options.

Additionally, it’s important to choose a reliable manufacturer with a proven track record of quality, support, and service within the industry.