High reputation Customized New Geit China Highway Guardrail Roll Forming Product Protecting Plate Machine Machinery Ztrfm

Our primary objective will be to offer you our shoppers a serious and responsible enterprise relationship, supplying personalized attention to all of them for High reputation Customized New Geit China Highway Guardrail Roll Forming Product Protecting Plate Machine Machinery Ztrfm, We have now experienced manufacturing facilities with a lot more than 100 workforce. So we could guarantee short lead time and top quality assurance.

Our primary objective will be to offer you our shoppers a serious and responsible enterprise relationship, supplying personalized attention to all of them for Highway Guardrail Roll Forming, We’ve been adhering to the philosophy of “attracting customers with the best items and excellent service”. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

MAIN TECHNICAL PARAMETERS

| Material | Cold rolled low carbon steel |

| Server system | YASKAWA |

| Steel belt width | ≤750mm |

| Production line speed | 15m/min |

| Electric control unit | PLC(Mitsubishi) |

MAIN COMPONENTS

1. Uncoiler

The machine is a single-head mode. With single support, the motor drives the material shaft of the uncoiler to release the material roll, and the hydraulic power drives the tension device of the material shaft of the uncoiler to fix the material roll on the material shaft of the uncoiler.

2. Uncoiler Parameter

| Allowable coil inner diameter | Ф508mm |

| Maximum allowable roll diameter | Ф1600mm |

| Maximum allowable roll width | 500 mm |

| Maximum roll carrying weight | ≤5000 kg |

| Uncoiler motor power | ≈5.5Kw (subject to the final design) |

3. Leveling Servo Feeder

The front of the leveling machine is also equipped with a telescopic shovel head and a material pressing device to ensure that the raw material rolls enter the leveling machine smoothly and safely.

| Maximum working speed | 40 m/min |

| Maximum leveling roll width | 500mm |

| Adapt to the maximum roll thickness | 2mm |

| Motor power of leveling machine: | ≈7.5Kw(subject to the final drawing design) |

4. Roller Forming Machine

The forming unit adopts an independent frame (housing mode). Motor, reducer drive, gear and chain drive.

| Forming Passes | about 13 |

| Shaft diameter of forming machine | φ80mm(subject to the final design) |

| Motor Power | about 55W(subject to the final design |

| Max. speed | 10~15m/min |

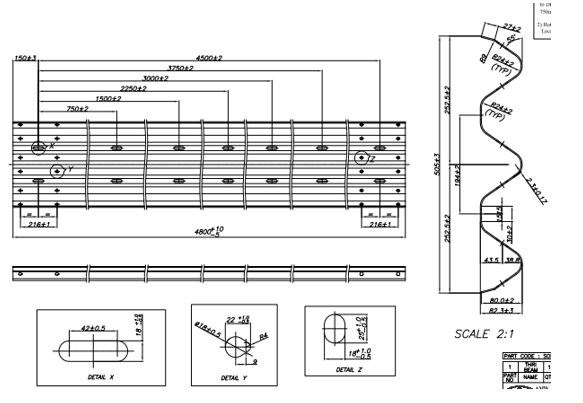

WORKPIECE SAMPLES

This is a 3 wave barrier made by our production equipment.

APPLICATION

Guardrails are widely used in industry, agriculture, municipal administration, transportation and other industries for decoration, maintenance and protection.

The guardrail forming machine is a special equipment for manufacturing guardrails for various purposes, such as highway safety guardrails, bridge guardrails, industrial safety guardrails, etc.

Roll forming machines are used to process steel coils into continuous strips of guardrail panels of specific shapes and sizes. It consists of several stations performing different operations such as decoiling, leveling, stamping, flow forming and cutting.

Additionally, some advanced guardrail roll forming machines may include additional features such as coating or paint systems for corrosion resistance, embossing devices for surface texture, or automatic control systems for precise production control. Guardrail roll forming machines offer high productivity and precision, enabling manufacturers to produce consistent, high-quality guardrail panels in high volumes.