Products

-

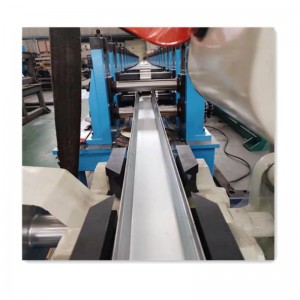

C U Z Purlin Roll Forming Machine

This line can produce C Z U and L shape metal profile on one machine, through only need to change some rollers.The uncoiler also contains 4 baffle plates to avoid the material from loosing during uncoiling.Main frame material:400# steel, thickness of Middle plate is 25mm. The main frame of machine is welded separately and the outside wall is connected by screw after being shot blasted on the surface. there are two purpose of being shot blasted: one, derusting. Two surface strengthening.

-

Gray Iron Casting CNC Gantry Moveable Drilling Machine For Tube

High Speed Gantry Moveable Drilling Machine mainly used for gantry and power unit, the processing plate, tapping and milling drilling of pipe fittings, can use carbide drill for internal cooling milling or high-speed milling steel flower drill for external cooling, the processing process is convenient, Able to automate operation, multi-piece, multi-production, production.

-

Cnc Gantry Moveable Planar Drilling Machine For Steel Structure

<iframe width=”560″ height=”315″ src=”https://www.youtube.com/embed/8bLhiwUniqA” title=”YouTube video player” frameborder=”0″ allow=”accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture” allowfullscreen></iframe>

PD2016 is a CNC Drilling machine for steel plates up to thickness 100mm. The positioning, feeding of three spindles are all driven by servo motors. It adopts Taiwan Precision Spindle, controlled by SIEMENS Control system, and Gantry movable type, high efficiency, and high precision. Both of external cooling twist drills and internal cooling carbide drills can be adopted on this machine. Very easy to operate, the automation, high precision, economics of scoop and mid/small production can be realized.

-

Metal coils cut to length line slitting line

The slitting line is also called slitting unit, slitting machine, slitting machine, and scissors. It cuts the metal coils into strips of various required widths, and then collects the strips into small rolls for the next process. It is a necessary equipment for precision cutting of transformers, motor industries and other metal strips. Raintech steel coil slitting line is designed according to our customers special requirements.Our slitting machine carries out slitting on cold or hot rolling carbon steel, tinplates, stainless steel, and other kinds of metal that have coated surfaces. It is a useful slitting machine, widely used during the processing of home appliances, automobiles, hardware, steel products and more.

-

Cable Tray Roll Forming Production Line

This cable tray production line is a specially equipment for cable tray roll forming,also can finish the production of its cover plate, which widely applicable in power transmission, machinery and equipment, commercial buildings and other facilities, including computer rooms, parking lots, data centers, offices, Internet service providers, hospitals, schools/universities, airports and factories.

This production line is mainly composed by following parts:

1. Uncoiler. Single support,four-bar tension structure, tension force comes from hydraulic cylinder, adjustment is fast and reliable.2. Leveler. It adopts 7 rollers for leveling, 2 pairs of guide rollers, feed rollers are pneumatically clamped, frequency conversion speed regulation, switch control.3. Looper ( Storage Material) Used to buffer the speed mismatch between the unwinding and leveling and the punching machine, and correct the deviation;4. Servo Feeder. The sheet is fed in according to the actual step length required for punching, and multiple sets of feeding parameters can be set at one time, which is convenient and quick

5. Multi-stations Punching&Cutting Unit. It adopts liquid four-column press mode, which is economical, applicable and fast. The punching machine has a 6-station punching mode and contains 3 to 4 sets of die sets, which can continuously punch out multiple types of holes.6. Cantilever adjustable forming machine . The forming unit adopts the cantilever forming machine mode. Motor, reducer, spiral bevel gear drive.When producing products with different bottom widths and waist heights, you only need to set the parameters on the touch screen, which is convenient, fast and reliable. -

Sheet Metal Cut to length Machine

Raintech design and produce the coil cut to length line according to different requirements from our customers. Also we can make small and compact cut to length line is suitable for the baby coils which max. Thickness 2mm, and coil width less than 600mm. Specially used for small coils cut into short steel plates. The whole line only 16 meters length, take very small space at your workshop. It’s the most economic and humane design.

-

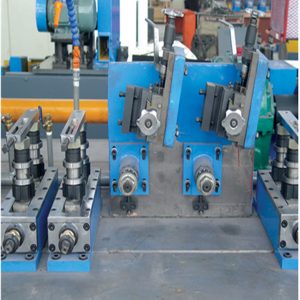

High Precision Tube Mill Production line

PROCESSING OBJECTS AND REQUIREMENTS

Purpose: The equipment is mainly used for polishing the outside surface of the stainless steel

The workpiece range requirements:

1.Workpiece diameter range:19-76mm2.Workpiece length range:6000mm

3.Final surface roughness:Ra 0.1 (Through surface friction many times)

4.Final finish requirements: Grinding and polishing

EQUIPMENT MAIN STRUCTURE AND PROPERITIES

The equipment mainly consists of one set of grinding head, a set of planetaryrotation system, a set of electrical control, a set of feeding system, a set of workpiece

receiving (releasing) mechanism, a set of dust removal system (optional).

1.Grinding head:

The machine is equipped with one set of grinding heads that can be used to polish the outside surface of the workpiece .According to the grinding

characteristics of the workpiece, use the abrasive belts as the grinding material. The grinding head consists of one polishing head motor, a support mechanism, a power drive mechanism, and a mounting plate.

2.Planetary rotation system:

The main function of this mechanism is to provide the required rotating motion of the grinding head during polishing. Motor power is

transmitted to the turnable through the V-belt to directly drive the turntable to rotate.It consists of a motor, turnable and a transmission device.

3.Electrical control:

The system’s role is to input instructions, control of the machine movement to achieve control, mainly by the console and the electronic

control cabinet, inverter and various low-voltage electrical components.

4.Feeding system:

Feeding system is used for automatic feeding of straight tube polishing.It consists of roller, feeder ,backlash adjusting screw and motor drive

system.

5.Workpiece receiving (releasing) mechanism:

This is for supporting workpieces during straight tube polishing.It consists of adjusting screw, rubber wheels and pallet.

6.Dust removal system (optional):

The role of this system is to collect the dust generated during the grinding process, to solve the dust collection, easy maintenance

and cleaning. It is mainly composed of a cyclone dust collector, a bag vacuum cleaner, and dust collection pipes. TECHNICAL PARAMETERS

Main technical performance parameters of the machine:No Project Reachability Indicators 1 Effectively polished diameter(mm) 19-76mm 2 Effectively polished length (mm) 6000 3 Final surface roughness Ra 0.1(Through surface friction many times) 4 Dust emission treatment Meet national standards (optional) Work environment requirements:

-

Hat Profile Roll Forming Machine

Hat channels are an alternative type of steel roof framing system, which can also be used as a purlin where a lower profile is required, or where the cover system requires closer purlin spacing thus making standard “Z” or “C” purlins overly expensive.

-

Color plate glazed tile 3d cutting automatic forming machine

The glazed tile roll forming machine is used to produce glazed tiles. Components: The glazed tile glazed tile forming machine is composed of charging rack, charging rack support, feeding guide device, forming host, punching device, forming shearing device, hydraulic station, computer control cabinet and other parts from the external structure. .The glazed tiles formed by the rolling die of this machine have the characteristics of beautiful appearance, simple and elegant, exquisite shape and noble taste, etc. They can be widely used in garden-style factories, tourist scenic spots, pavilions, hotels, villas, exhibition halls, resorts, etc. Home and other buildings and outdoor decoration

-

Stainless Steel Cut To Length Line

The cut to length line is also known as the horizontal shearing line, the leveling machine, the flattening line, and the horizontal shearing unit. Its operation is simple and reliable, and the stacking is neat. High degree of automation, high precision of fixed length, and high flatness of sheet metal.

-

76mm Tube Mill Line Pipe Mill Line

High frequency welding is used in the production of steel welded pipes. High frequency welding has larger power supply, and higher welding speed can be achieved for steel pipes with different material, caliber and wall thickness.

-

Solar strut roll forming machine

The solar strut roll forming machine specially do the process of punching holes, forming rolling of the solar strut bracket , PV stand rack .