Professional China Railway Stainless Steel Roofing/Wall/Floor Deck Making Roll Forming Machine

The key to our success is “Good Product Excellent, Reasonable Rate and Efficient Service” for Professional China Railway Stainless Steel Roofing/Wall/Floor Deck Making Roll Forming Machine, Sincerely hope to build long term business relationships with you and we will do our best service for you.

The key to our success is “Good Product Excellent, Reasonable Rate and Efficient Service” for China Roofing Machine and Building Machine, Our company is an international supplier on this kind of merchandise. We offer an amazing selection of high-quality products. Our goal is to delight you with our distinctive collection of mindful products while providing value and excellent service. Our mission is simple: To provide the best products and service to our customers at the lowest prices possible.

PRODUCT APPLICATION

MAIN TECHNICAL PARAMETERS

Material: Galvanized cold-rolled sheet

Yield strength of raw materials: ≤275Mpa

Tensile strength of raw materials: ≤550Mpa

Coil OD: ≤Ф1300 mm

Coil ID: Ф508

Strips width: ≤1450mm

Strips thickness: 0.8~1.2mm

Coil weight: ≤10000 kg

MAIN COMPOSITIONS

| No | Items Name | Specifications |

| 1 | Decoiler | Single head mode, single support; Coil ID: Ф508; Coil OD: Ф1300mm; Strips width: 1450 mm; Max. Weight: ≤10000 kg |

| 2 | Roll Forming Machine |

Structure: the forming unit is driven by motor reducer chain; Forming stations:36 stations; Forming machine shaft dia:φ95mm; Motor power: 22kwX2; Max: 15m/min |

| 3 | Hydraulic Cutting | The cutter mode adopts blanking shearing; Blade material: Cr12MoV (hardness after quenching HRC58~62); Parameter: cutting accuracy:±1.5mm |

| 4 | Electrical Control Cabinet |

Main electrical components; PLC: Mitsubishi; Inverter: delta ; Touch screen: veron (Taiwan, China) ; Low-voltage electrical appliances: schneider (France) ; Encoder: Omron (Japan) |

| 5 | Hydraulic System | Hydraulic system USES filter, the cleanliness of oil to ensure 6-8 grade |

| Run-out Table | Size: 3*1.2*0.6m; Adjustable Height |

PRODUCTION PROCESS

Uncoling → Flatterning → Roll Forming → Dischaging

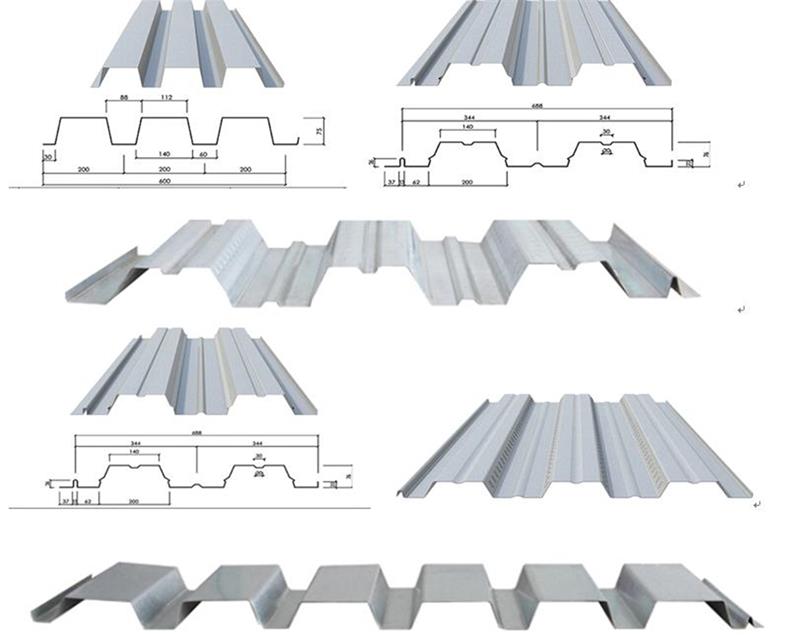

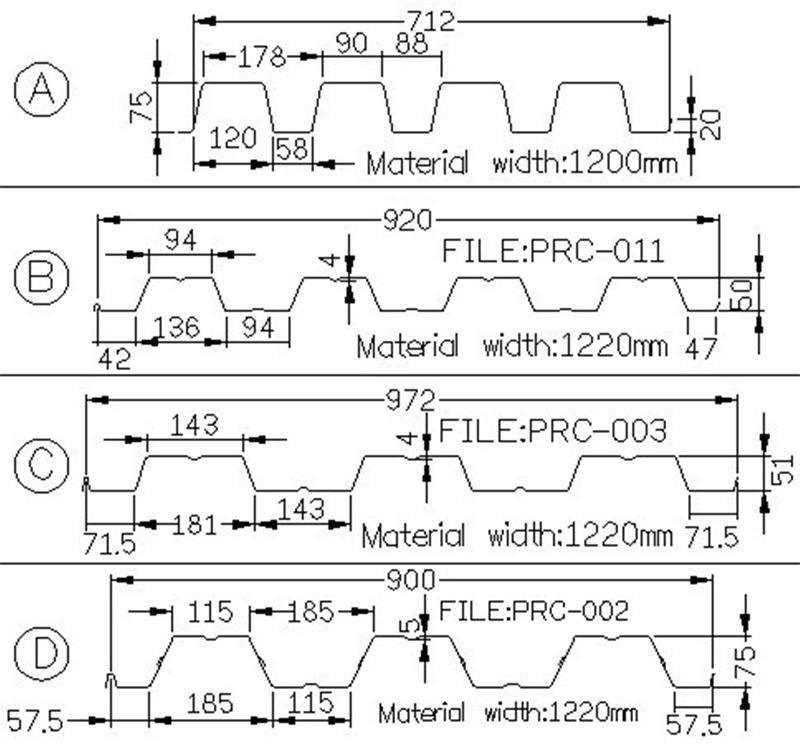

WORKPIECE SAMPLES

Metal decking is corrugated metal sheeting that’s used as a structural roof deck or composite floor deck. It will be supported by steel beams or joists The purpose of metal deck is to support the insulating membrane of a roof or to support and bond with the concrete to create a composite metal floor deck.

Floor roll forming machines are equipment used in the construction industry to manufacture floor coverings. It is designed to continuously transform sheet metal into the desired shape by feeding it into rollers that gradually bend and shape the metal. The machine can produce different types of floor trim panels, such as corrugated panels or profiled panels, according to the specific requirements of the project.

A typical process involves feeding a flat coil of metal into the machine, which passes through a series of rollers that gradually shape the metal into the desired floor finish profile. The machine is equipped with adjustable cutting tools to cut the metal to the desired length. Finished floor panels can be used to construct floors, mezzanines and other structural elements.

Floor roll forming machines are usually automated and operated by a control system that allows precise control and adjustment of the machine’s settings. This ensures consistent and high quality floor panel production. These machines are often used in large construction projects where floor panels need to be produced efficiently and cost-effectively. They can be tailored to the specific needs of a project to produce different types of profiles and sizes.