Featured Products

-

High Performance Top Quality Highway Guardrail Roll Forming Machine Three Wave Roll Forming

Guardrail C-post gains popularity type due to their low cost, high safety, and environmental protection. This type of post is the most common applied post in highway guardrail projects and can be hammered with different types of hammers.Provide customized C-post highway guardrail posts of different sizes, with high cost performance, reasonable price and stable performance

-

ODM Factory High Quality Factory Price Dcr Series CNC Angle Band Sawing Machine for Steel Tower

Product Description

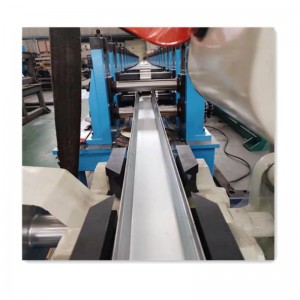

The Vehicle Bumper Beam Roll Forming Machine Include :

Roll forming machine 1 set

Hydraulic cutter 1 set

Electrical control system 1 set

Hydraulic system 1 set

Manual de-coiler 1 set Max. loading 5 T

Technical specification and details

(1) Hydraulic Ue-coiler

Un-power: manual de-coiler; Max. Capacity: 7T

Suit for coil inner diameter: 508mm, suitable coil Max. out diameter: 1000mm

Manual power expands the coil inner surface.

(2) Roll forming machine

1) Number of forming steps: 15 steps

2) Material of shaft: 45# steel hardening and tempering treatment. Outer diameter 85mm ,total solid Tolled shafts

3) Rollers: Material is high grade No.45 forged steel, with digital-controlled procession. The rollers are plated with hard chrome with thickness of 0.05mm on the surface after being machined by the exact machine tool. So that to ensure long life of forming rollers.

4) Main motor power: 4 KW with cyclical planetary gear speed reducer

5) The plating chromium’s thickness on the surface of rollers: 0.05mm

6) Main stand: 350# H steel welded structure Wall plate thickness: 14mm the main frame of machine is welded separately and the outside wall is connected by screw after being rot blasted on the surface.

7) Chain and gear move the line, motor drives. All working actions are controlled by PLC electric cabinet automatically.

8) Suitable power voltage: 380V/50HZ/3Phase (can de designed according to buyer’s requirement)

9) Line working speed (Forming speed): about 15-18 m/min (without cut time)

10) Main machine motor power: about 5.5 KW (Depend on final design)

Dimension of the machine: 9000mmx1200mmx1200mm

Weight of the machine: about 5000kg

(3) Hydraulic Cutting

1) Adopts post cutting, Stop to cut;

2) The cutting blade material is Cr12 with quenched treatment.

3) Adopts welded frame for good rigidity.

4) Cutting frame has been heat treatment to avoid final product deformation. cutting length tolerance ±2mm.

5) The power of cutting is provided by hydraulic station.

6) The final product can be cut as per set length in PLC controller, and the length is automatically measured by encoder. When final product reaches the set length, machine will stop to cut the Product automatically. Finish this action, machine will run again continuously.

(4) Hydraulic station

1) It supplies the power for the hydraulic cutter.

2) All hydraulic accessories are all use Chinese famous brand products.

3) Hydraulic motor power: 3KW

(5) PLC Control System

1) This system uses Delta PLC to control the all working actions. Production quantity and each piece length will be automatically measured. It is convenient to control the roll forming machine.

2) Delta converter adjusts speed technology, realize the automatic production.

3) Text screen is input and cancelled the working data.

4) Friendly man-machine interface system can be set batches to the work piece, length, quantity, etc.

5) Encoder count, having function of count and measuring length.

6) Suitable power voltage: 380V/50HZ/3Phase (can de designed according to buyer’s requirement)

-

100% Original dB76 SGS Scaffolding ERW Steel Tube Mill

The tube milling line is straight seam welding on welding equipment from steel pipes made of hot-rolled or cold-rolled steel sheets or coils.

-

high quality auto U beam roll forming machine

The u beam roll forming machine can complete the forming of beam profiles. Other similar cold-formed steels can also be produced by replacing rolls and related tools and dies. Our equipment is mainly for the production of automobile beam panels. Automobile girder plates are mainly used to manufacture automobile longitudinal beams, cross beams, front and rear axles, bumpers and other structural parts. The thickness is generally 4.0-8.0mm. It is a steel grade with high demand for automobile structural steel plates and high performance indicators.

-

high professional floor decking roll forming machine with nice price

Floor decking roll forming machine is manually used to produce steel floor decking and can produce high quality floor decking has advantages, such as no cutting deformation, high strength and a large working load. It can be directly mixed with the steel mesh and concrete with good adhesion. The main applications of decking sheets include thermal power plant, multilayer car shade parking, multi-story residential and commercial buildings such as shopping malls, bridges, platforms, walkways, mezzanines, silos, etc.

-

5% Discount Raintech truck side plate roll forming machine

Truck carriage wall plate roll forming machine is mainly used to produce the parts on the truck, including the bottom plate, the top plate and the column on the truck. It can be applied to refrigerated trucks, large trucks, trucks, etc.

-

high professional hot sale light gauge steel keel rool forming machine

This light steel keel production line used to produce “villa keel”. The light steel villa forming machine reads the complete set of keel component structure designed by Vertex BD software from the U disk, and laps them together to form a complete light steel villa frame.

This production line has widen application, mainly include: private apartments, single-family villas, express hotels, automobile hotels; roll-formed thin-walled light-steel structure buildings such as buildings, modular houses, commercial and industrial buildings, as well as buildings for emergency and disaster relief, disaster relief, and post-disaster reconstruction houses.

-

High Professional Guardrail Beam Roll Forming Machines For Sale

Highway guardrail roll forming machine is mainly used to produce highway guardrail. This machine used for punching, forming and cutting of the highway guardrail corrugated plate, which widely used in bridge, highway construction.

-

8 Years Exporter Customized Metal Furring Top Hat Profile Ceiling Omega Profile Light Steel Keel Roll Forming Machine Manufacturer

Hat channels are an alternative type of steel roof framing system, which can also be used as a purlin where a lower profile is required, or where the cover system requires closer purlin spacing thus making standard “Z” or “C” purlins overly expensive.

-

Cheap PriceList for Wholesale Ibr Tr4 Tr5 Tr6 Steel Glazed Corrugated Double Layer Deck and Step Tile Roll Forming Machine Roofing Sheet Building Material Making Machinery Price

This glazed tile roll forming machine is used for making the glazed tile,which is widely used in factories, houses, hotels, villas and other industrial and civil buildings.

-

OEM/ODM China Eps Sandwich Panel Making Machine Sandwich Panel Machine Production Line Sandwich Panel Roll Forming Machines

Rock wool foam sandwich panel dual-use composite machine equipment is made of high quality color steel plate and light inner core material, through the special composite production line made of one or two sides of the outer layer, forming a high strength, light weight, good heat insulation effect of a new type of construction and decoration materials.

Because of its strong and durable, beautiful appearance and convenient construction, low cost is welcomed by all walks of life, is widely used in industrial plants, large warehouses, large span roof, walls, simple rooms, kiosks, cold storage, purification room, air conditioning room and other places.

-

Personlized Products Roll Forming Machine for Solar Struct Solar Panel Structure

This solar photovoltaic bracket is the production of solar photovoltaic brackets. The solar photovoltaic bracket is a special bracket designed for placing, installing and fixing solar panels in the solar photovoltaic power generation system. The general materials are aluminum alloy and stainless steel. Photovoltaic support products are divided into ground support system, flat roof support system, adjustable angle roof support system, inclined roof support system, column support system, etc.